- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

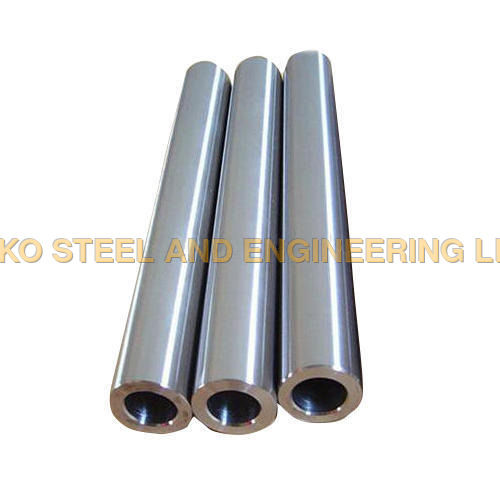

Ss Round Bar

160 INR/Kilograms

Product Details:

- Size Custom / Standard Lengths: 1 Meter, 3 Meter, 6 Meter

- Diameter 6mm 250mm

- Heat Resistance Yes

- Hardness 160 - 250 HB (as per grade)

- Corrosion Resistant Yes

- Product Form Solid Bar

- Tensile Strength 520 - 700 MPa (as per grade)

- Click to view more

X

Ss Round Bar Price And Quantity

- 160 INR/Kilograms

- 100 Kilograms

- Hot Rolled / Cold Drawn / Forged

- High

- 200 GPa

- Good

- 1 Ton / Custom

- Bundled / Wooden Box / Customized

- Ready stock / As per order

- 40% (typical for SS 304)

- 1400 1450C

- 7.98 g/cm

- Stainless Steel Round Bar

Ss Round Bar Product Specifications

- 6mm 250mm

- Stainless Steel

- Bright, Polished, Black

- 6mm 250mm

- Varies depending on size

- Custom / Standard Lengths: 1 Meter, 3 Meter, 6 Meter

- Structural support, Shafts, Tool manufacturing, Mechanical parts

- Iron, Chromium, Nickel, Carbon, Manganese (varies as per grade)

- Yes

- None / Uncoated

- ASTM, DIN, JIS, BS, IS

- 304, 316, 202, 410, 420, 430, Duplex and others

- Round Bar

- 18% Chromium, 8% Nickel (AISI 304 standard example)

- 520 - 700 MPa (as per grade)

- Solid Bar

- Ss Round Bar

- Yes

- Silver/Grey

- 160 - 250 HB (as per grade)

- Yes

- 304/316/202/410/420/430

- Custom / As per requirement

- Round

- Construction, Engineering, Manufacturing, Automotive, Railways, Shipbuilding, Industrial Machinery

- Bright, Polished, Black, Matte, Peeled

- Hot Rolled / Cold Drawn / Forged

- High

- 200 GPa

- Good

- 1 Ton / Custom

- Bundled / Wooden Box / Customized

- Ready stock / As per order

- 40% (typical for SS 304)

- 1400 1450C

- 7.98 g/cm

- Stainless Steel Round Bar

Ss Round Bar Trade Information

- Cheque

- 100 Kilograms Per Day

- 1 Week

- Within a certain price range free samples are available

- All India

Product Description

SS Round Bar

The offered SS Round Bar is available in a variety of sizes and is extremely corrosion resistant. Various applications for this bar include axles, frameworks, shafts, supports, and braces, to name a few examples. Generally speaking, this bar is a cylindrical and long metal bar with various industrial and commercial applications. It is one of the most important components of any production sector or any industry that is generally reliant on machinery. Our SS Round Bar is found at the heart of nearly every engineering industry, including earthmoving equipment, automotive, aerospace, textile, cement, and defense, to name a few.

Versatile Manufacturing Techniques

Ss Round Bars are produced using hot rolled, cold drawn, or forged methods, ensuring optimum mechanical properties for varied applications. Each process influences finish, tolerance, and structural integrity. Clients may choose the technique that best fits their requirements for surface quality, dimensional accuracy, and performance.

Customizable for Diverse Industries

Engineered for sectors such as automotive, construction, shipbuilding, and industrial machinery, Ss Round Bars come in customized sizes, thicknesses, and grades. Options include dimensions ranging from 6mm to 250mm in diameter and finishes like polished, bright, matte, or peeled, facilitating use in shafts, tool manufacturing, and structural supports.

Strength, Durability, and Ease of Fabrication

With tensile strength between 520-700 MPa and hardness up to 250 HB, Ss Round Bars offer high elongation, corrosion resistance, and heat tolerance up to 870C. Their good machinability and high weldability make them suitable for intricate engineering processes and robust mechanical applications.

FAQs of Ss Round Bar:

Q: How is the Ss Round Bar manufactured?

A: Ss Round Bars are produced using hot rolled, cold drawn, or forged techniques. Each method affects the mechanical properties, surface finish, and tolerances, giving flexibility to match engineering needs.Q: What applications can Ss Round Bars be used for?

A: These round bars are utilized in construction, engineering, automotive, railways, shipbuilding, and industrial machinery, where strength, corrosion resistance, and precise dimensions are required for structural supports, shafts, and tools.Q: When can I receive my order of Ss Round Bars?

A: Ready stock is available for immediate dispatch, while customized sizes, grades, or finishes are supplied as per order, typically depending on project requirements and quantity.Q: Where are Ss Round Bars typically sourced and supplied?

A: They are manufactured, supplied, and exported from India by various producers, meeting international standards such as ASTM, DIN, JIS, and BS for global engineering projects.Q: What is the process for customizing diameter, length, and surface finish?

A: Customers can specify preferred diameter (6mm to 250mm), length (1m, 3m, 6m, or custom), and finish (bright, polished, black, matte, peeled) during ordering. Manufacturers adjust production accordingly to meet individual specifications.Q: What are the benefits of using stainless steel round bars in construction and machinery?

A: Ss Round Bars offer high tensile strength, excellent weldability, good machinability, corrosion resistance, and durability, making them ideal for structural supports and critical mechanical components in demanding environments.Q: How is Ss Round Bar typically packaged for delivery?

A: They are packaged in bundles, wooden boxes, or customized packaging depending on order size and customer preferences, ensuring safe transport and preservation of surface quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese