- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

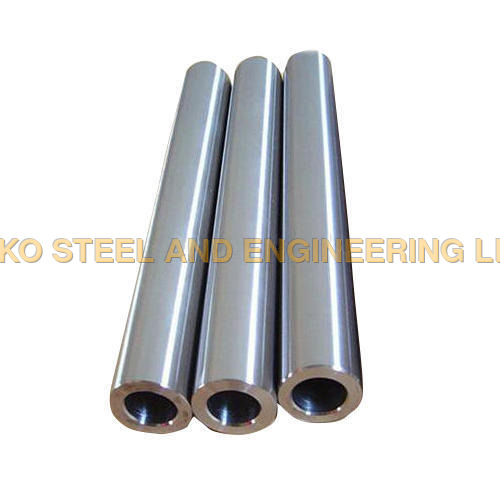

Inconel 718 Seamless Tube

160 INR/Kilograms

Product Details:

- Coating Type Uncoated / As required

- Size Custom sizes available

- Corrosion Resistant Yes

- Diameter 6 mm 219 mm

- Material Composition % Nickel 50-55%, Chromium 17-21%, Iron Balance, Niobium + Tantalum 4.75-5.5%, Molybdenum 2.8-3.3%, Titanium 0.65-1.15%, Aluminum 0.2-0.8%

- Product Form Seamless Tube

- Tensile Strength Min 1240 MPa

- Click to view more

X

Inconel 718 Seamless Tube Price And Quantity

- 160 INR/Kilograms

- 100 Kilograms

- 160.00 - 190.00 INR/Kilograms

- Min 1035 MPa

- Good machinability and weldability

- Austenitic

- 13201390C

- Excellent cold and hot workability

- 12% Min

- ASTM, ASME, DIN, EN

- Supplied with material test certificate

- 8.19 g/cm

Inconel 718 Seamless Tube Product Specifications

- Inconel 718

- Yes

- As per Size and Length specification

- Seamless Tube

- Rockwell C32 Max

- 0.5 mm 20 mm

- Polished / Bright / Annealed

- Yes

- Min 1240 MPa

- Nickel-Chromium Superalloy

- Customizable as per requirement

- High temperature & high pressure applications

- Round Tube

- Aerospace, Gas Turbine Engines, Nuclear Reactors, Oil & Gas, Chemical Processing

- Seamless Tube

- UNS N07718

- 6 mm 219 mm

- Nickel, Chromium, Iron, Niobium, Molybdenum, Titanium, Aluminum

- Inconel 718 Seamless Tube

- Nickel 50-55%, Chromium 17-21%, Iron Balance, Niobium + Tantalum 4.75-5.5%, Molybdenum 2.8-3.3%, Titanium 0.65-1.15%, Aluminum 0.2-0.8%

- Silver / Metallic

- Uncoated / As required

- Polished / Bright

- Custom sizes available

- Yes

- ASTM B163, ASTM B444, ASTM B516, ASTM B705

- Min 1035 MPa

- Good machinability and weldability

- Austenitic

- 13201390C

- Excellent cold and hot workability

- 12% Min

- ASTM, ASME, DIN, EN

- Supplied with material test certificate

- 8.19 g/cm

Inconel 718 Seamless Tube Trade Information

- 100 Kilograms Per Day

- 1 Week

Product Description

Inconel 718 Seamless Tube

The offered Inconel 718 Seamless Tube is a nickel-based alloy that has been precipitation hardened. It is used in the aerospace industry. In addition to having extremely high yield strength and tensile strength, this tube also has excellent creep-rupture properties, making it a perfect choice for use in various industrial applications. Welding an age-hardened Inconel metal, however, can result in the formation of a heat-affected region. Similar to the welding operation, our Inconel 718 Seamless Tube can be easily machined in either the annealed or the age-hardened condition, depending on their size and shape. In general, machining our tube in age-hardened operational conditions results in a better surface finish than machining it in a soft state. Meanwhile, manufacturing and annealed condition tube can result in elongated tool life.

Unmatched Strength and Heat Resistance

Inconel 718 Seamless Tubes exhibit exceptional heat resistance up to 700C, coupled with a minimum yield strength of 1035 MPa and tensile strength of 1240 MPa. This ensures reliable performance under high-pressure and high-temperature conditions, typical in aerospace and industrial applications. Its polished and bright finish also adds to its suitability for demanding operations.

Custom Fabrication for Diverse Applications

Manufacturers offer Inconel 718 seamless tubes in customizable sizes and thicknesses ranging from 0.5 mm to 20 mm and diameters from 6 mm to 219 mm. With excellent cold and hot formability, these tubes can be tailored for unique requirements in sectors such as energy, chemical processing, and gas turbine engineering.

Corrosion and Oxidation Protection

Composed primarily of nickel, chromium, and alloying elements like niobium and molybdenum, Inconel 718 provides outstanding resistance to corrosion and oxidation. This characteristic enables long service life even in chemically aggressive or extreme environments, minimizing maintenance and replacement cycles.

FAQs of Inconel 718 Seamless Tube:

Q: How is Inconel 718 Seamless Tube utilized in high-temperature applications?

A: Inconel 718 Seamless Tube is commonly used in environments exceeding 700C, such as gas turbine engines, aerospace components, and nuclear reactors, due to its superior heat resistance and mechanical stability under thermal stress.Q: What certifications and standards do these tubes comply with?

A: These tubes are compliant with international standards such as ASTM B163, ASTM B444, ASTM B516, ASTM B705, ASME, DIN, and EN. Each shipment is accompanied by a detailed material test certificate confirming quality and composition.Q: When should Inconel 718 be selected over other alloys?

A: Inconel 718 is chosen when applications demand robust strength, excellent formability, and resistance to both corrosion and intense heat, as found in aerospace engineering, gas turbines, and chemical processing plants.Q: Where are Inconel 718 Seamless Tubes commonly sourced and supplied?

A: These tubes are globally exported, imported, and supplied by reputable manufacturers, suppliers, and exporters based in India and worldwide, catering to industries requiring high-performance materials.Q: What is the fabrication process like for Inconel 718 Seamless Tube?

A: Inconel 718 offers good machinability and weldability, allowing efficient cold and hot forming into seamless tubes with customizable dimensions to match client specifications.Q: How does the microstructure of Inconel 718 affect its performance?

A: The austenitic microstructure of Inconel 718 imparts high tensile strength, excellent ductility (12% minimum elongation), and robust resistance to mechanical and thermal fatigue, enhancing its reliability across challenging operational scenarios.Q: What are the key benefits of using Inconel 718 Seamless Tube?

A: Key benefits include remarkable resistance to heat and corrosion, outstanding mechanical properties, diverse customization options, recyclability, and a long service life in severe conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese