- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

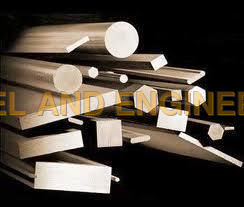

Nickel Alloy Round Bars

160.00 - 190.00 INR/Kilograms

Product Details:

- Flexibility Rigid

- Tolerance 0.05 mm

- Sealing Type Solid Bar - No Sealing

- Temperature Range Up to 1200C

- Connection Type Solid Bar

- Bend Radius Rigid (Not Applicable)

- Yield Strength 140 MPa (Approx., Varies by Grade)

- Click to view more

X

Nickel Alloy Round Bars Price And Quantity

- 160.00 - 190.00 INR/Kilograms

- 20 Kilograms

- 80-100 HB (Approx., Varies by Grade)

- Good

- Bright/Polished

- 8.89 g/cm³

- Excellent in Various Media

- Hot Rolled / Cold Drawn

- Standard Seaworthy Export Packing

- Ultrasonic and Physical Testing Available

Nickel Alloy Round Bars Product Specifications

- Round

- Round

- 3 mm to 300 mm

- Not applicable (Solid Bar)

- 480 MPa (Approx., Varies by Grade)

- Industrial, Chemical Processing, Marine

- 140 MPa (Approx., Varies by Grade)

- 1 m to 6 m or Custom

- 3 mm to 300 mm

- Construction, Oil & Gas, Power Plants, Chemical Industry

- Rigid (Not Applicable)

- ASTM, ASME, DIN, EN

- Solid Bar

- Solid Bar (Not Threaded)

- Nickel Alloy

- Custom as required

- Nickel Alloy 200 / 201 / Custom Grades

- Up to 1200C

- Round Bar

- Polished

- Solid Bar - No Sealing

- Silver Grey

- 0.05 mm

- Rigid

- 80-100 HB (Approx., Varies by Grade)

- Good

- Bright/Polished

- 8.89 g/cm³

- Excellent in Various Media

- Hot Rolled / Cold Drawn

- Standard Seaworthy Export Packing

- Ultrasonic and Physical Testing Available

Nickel Alloy Round Bars Trade Information

- 1 Kilograms Per Day

- 1 Days

Product Description

Nickel Alloy Round Bars find application in marine, communication, medical, construction, oil & gas, and power generation industries. They are highly appreciated for superior structural hardness, ductility, tensile strength, and special magnetic properties. These structures can easily be shaped into desired products with help of advanced machines. They are also considered to have excellent corrosion resistance and ensure effective use even at high temperatures. Nickel Alloy Round Bars are also suitable for fabrication of propeller shafts of boats and turbine blades. These bars are perfect for cryogenic conditions as well and are required for making Euro, UK, & U.S coins.

Superior Corrosion Resistance

These Nickel Alloy Round Bars deliver outstanding performance in corrosive environments such as marine, chemical, and industrial settings. Their inherent resistance to oxidation and various chemicals makes them a preferred material for applications where durability and longevity are essential.

Versatile Manufacturing Techniques

Available through hot rolling or cold drawing methods, these bars provide flexibility for diverse engineering and structural requirements. The bright, polished surface not only enhances aesthetics but also ensures optimal material integrity, making them suitable for high-impact and precision-demanding projects.

FAQs of Nickel Alloy Round Bars:

Q: How are Nickel Alloy Round Bars manufactured to ensure quality and performance?

A: Nickel Alloy Round Bars are produced using either hot rolled or cold drawn processes and are tested ultrasonically and physically to ensure precise tolerances, solid construction, and consistent performance across various industrial applications.Q: What makes these round bars suitable for harsh environments and chemical applications?

A: Their excellent corrosion resistance in various media, combined with good machinability and high-temperature tolerance up to 1200C, make them ideal for use in chemical processing, marine environments, and power plants, where reliability is critical.Q: When is it beneficial to choose custom diameters and lengths for Nickel Alloy Round Bars?

A: Custom sizing enables manufacturers and engineers to meet specific project requirements for construction, oil and gas, and industrial installations, ensuring optimal safety, fit, and structural integrity.Q: Where are Nickel Alloy Round Bars commonly used in industry?

A: These bars are widely utilized in sectors such as construction, chemical industry, oil & gas, power plants, and marine applications that demand superior strength, corrosion resistance, and rigid form properties.Q: What testing methods are employed before export packing?

A: Each bar undergoes ultrasonic and physical testing to validate structural soundness and compliance with international standards before being packed in standard seaworthy export packaging for safe global shipment.Q: How does the polished surface benefit the products performance and appearance?

A: A polished surface improves corrosion resistance, reduces the risk of contaminant buildup, and enhances the bars visual appeal, making it suitable for exposed installations and precision engineering purposes.Q: What advantages do Nickel Alloy Round Bars offer over other materials in demanding environments?

A: Nickel Alloy Round Bars offer superior durability, excellent mechanical properties, and exceptional resistance to corrosion and high temperatures, making them more reliable and longer-lasting than many conventional materials in challenging industrial scenarios.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese