- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

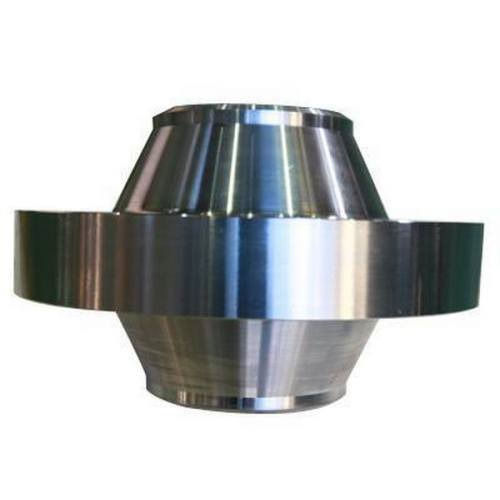

Stainless Steel Ferrules

160 INR/Kilograms

Product Details:

- Recyclable Yes

- Corrosion Resistant Yes, excellent corrosion resistance

- Coating Type Uncoated

- Product Form Ferrule / Coupling Sleeve

- Material Composition % 18% Cr, 8% Ni (Grade 304, typical)

- Heat Resistance Yes

- Diameter 1/8 to 2 (NPT) or as per custom requirement

- Click to view more

X

Stainless Steel Ferrules Price And Quantity

- 160 INR/Kilograms

- 160.00 - 190.00 INR/Kilograms

- 100 Kilograms

- Single and Double Ferrule Design

- Yes

- Compatible with metric & imperial tubes

- Bulk / Customized Packaging

- -196°C to +870°C (varies with grade)

- Precision Machined

- Yes

- Compression/Mechanical Grip

- Up to 6000 psi, depending on size and material

Stainless Steel Ferrules Product Specifications

- Yes

- Silver

- Yes, excellent corrosion resistance

- Varies with size and type

- Industrial Fittings, Tube Connections, Wiring Applications

- Cr-Ni (Chromium-Nickel)

- Polished / Matte

- Uncoated

- Pipe Fittings, Hydraulic & Pneumatic Connections, Cable Assemblies

- 304 / 316 / 316L

- 0.5 mm to 3 mm

- Round, Cylindrical

- Ferrule

- Ferrule / Coupling Sleeve

- Stainless Steel Ferrules

- 18% Cr, 8% Ni (Grade 304, typical)

- Yes

- 1/8 to 2 (NPT) or as per custom requirement

- 304, 316, 316L, 321

- Bright / Satin

- Stainless Steel

- Varies (customized)

- 515-690 MPa (varies by grade)

- Customized as per requirement

- ASTM A240 / A276 / A182

- 85-95 HRB (for 304 grade)

- Single and Double Ferrule Design

- Yes

- Compatible with metric & imperial tubes

- Bulk / Customized Packaging

- -196°C to +870°C (varies with grade)

- Precision Machined

- Yes

- Compression/Mechanical Grip

- Up to 6000 psi, depending on size and material

Stainless Steel Ferrules Trade Information

- 100 Kilograms Per Day

- 1 Week

Product Description

Stainless Steel Ferrules

The Stainless Steel Ferrules that we offer are utilized on tiny ID hoses that carry air, water, and other non-critical applications. Compared to longer and heavier crimp sleeves, they offer a more cost-effective choice. Our ferrules must be placed using larger crimping machines to ensure a smooth and consistent grip. Stainless Steel Ferrules are also compatible with stainless or brass barbs, Double Lock Cplgs, Twist Lock Cplgs, and Lug Universals, among other things.

Engineered for High-Performance Applications

Our stainless steel ferrules offer reliability and durability, performing across a wide temperature range from -196C to +870C, depending on the stainless steel grade. Tailored for pipe fittings, hydraulic, pneumatic, and cable assembly applications, these ferrules maximize safety in harsh environments. Select from a variety of shapes, thicknesses, and finishes to meet your specific project requirements. Each piece is subjected to stringent quality standards to ensure optimal strength and longevity.

Versatile Design & Customization Options

Available in single and double ferrule designs, these stainless steel ferrules accommodate both standard and unique connection needs. Customers can order in standard sizes or request fully customized dimensions, thicknesses, and finishesranging from polished to matte. Whether you need ferrules for new installations, retrofits, or specialized industrial projects, we provide tailored solutions and bulk packaging options.

FAQs of Stainless Steel Ferrules:

Q: How are stainless steel ferrules manufactured to ensure precision and reliability?

A: Stainless steel ferrules are produced using precision machining processes, which maintain tight tolerances and uniform dimensions. This manufacturing technique results in reliable, leak-free connections, even under high pressure or temperature fluctuations. Each ferrule also complies with stringent ASTM standards for material composition and strength.Q: What benefits do stainless steel ferrules offer compared to other materials?

A: Stainless steel ferrules provide excellent corrosion and heat resistance, high tensile strength (515-690 MPa), and durability. Their resistance to harsh chemicals and extreme temperatures, along with a variety of available grades (304, 316, 316L, 321), makes them suitable for demanding industrial and environmental conditions.Q: Where can these ferrules be used in industrial applications?

A: These ferrules are ideal for pipe fittings, hydraulic and pneumatic connections, cable assemblies, tube connections, and wiring applications. Their compatibility with metric and imperial tubes makes them versatile for use in industries such as oil and gas, instrumentation, chemical processing, and general manufacturing.Q: What is the process for selecting the right ferrule for my application?

A: Begin by determining your required operating pressure, temperature range, and the medium type. Choose the appropriate stainless steel grade, shape, and thickness, then verify compatibility with your tubing size (metric or imperial). Our team can assist with custom sizes and finishes should you have specialized requirements.Q: When should single vs. double ferrule designs be specified?

A: Single ferrule designs are typically used for general-purpose applications where ease of installation and cost-effectiveness are priorities. Double ferrule configurations provide enhanced sealing integrity and resistance to vibration, making them preferable for high-pressure and critical system connections.Q: Are these ferrules environmentally friendly and compliant with regulations?

A: Yes, our ferrules are RoHS-compliant, lead-free, and fully recyclable. They are manufactured to meet international safety and environmental standards, ensuring suitability for export and use in regulated industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese