- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

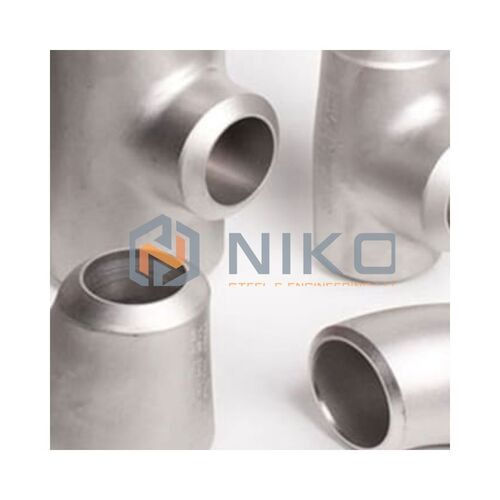

SS 317L BUTTWELD FITTINGS

200 INR/Kilograms

Product Details:

- Tensile Strength 515 MPa min

- Thread Type NA (Buttweld type)

- Temperature Range -196C to 870C

- Yield Strength 205 MPa min

- Connection Type Welded

- Diameter 12.7 mm to 609.6 mm

- Tolerance 0.5 mm

- Click to view more

X

SS 317L BUTTWELD FITTINGS Price And Quantity

- 300 Kilograms

- 200 INR/Kilograms

- RoHS, REACH

- Beveled ends

- 11.0 - 15.0%

- Hydrostatic, PMI, NDT as per request

- Ready stock / As per order

- 7.9 g/cm³

- Smooth, burr-free

- Export quality wooden cases / pallets

- Brinell 217 HB max

- 3.0 - 4.0%

- Seamless / Welded

- Excellent against acids, chlorides, and sulfur compounds

SS 317L BUTTWELD FITTINGS Product Specifications

- Rigid

- Elbow, Tee, Reducer, Cap, Stub End

- Custom/Standard as per fitting type

- Metal-to-metal

- Industrial, Chemical Processing, Oil & Gas, Power Plant

- Buttweld Fittings

- 0.5 mm

- Stainless Steel

- Uncoated/As supplied

- SS 317L (UNS S31703)

- 1D, 1.5D, 2D and custom

- SCH 10, SCH 40, SCH 80 (custom as required)

- Round

- Pickled, Passivated

- -196C to 870C

- Pipeline, Process Industries, Chemical, Petrochemical, Oil & Gas

- 1/2 to 24 (DN15~DN600)

- 515 MPa min

- NA (Buttweld type)

- ASTM A403 / ASME SA403

- 12.7 mm to 609.6 mm

- Welded

- Class 150# to 2500#

- Buttweld

- Silver / Metallic

- 205 MPa min

- RoHS, REACH

- Beveled ends

- 11.0 - 15.0%

- Hydrostatic, PMI, NDT as per request

- Ready stock / As per order

- 7.9 g/cm³

- Smooth, burr-free

- Export quality wooden cases / pallets

- Brinell 217 HB max

- 3.0 - 4.0%

- Seamless / Welded

- Excellent against acids, chlorides, and sulfur compounds

SS 317L BUTTWELD FITTINGS Trade Information

- Cash Advance (CA)

- 1 Kilograms Per Day

- 1 Days

- All India

Product Description

317L Stainless Steel Buttweld Fitting Supplier.

NIKO STEEL AND ENGINEERING WORKS is one of the industry-leading manufacturers, traders, suppliers, and exporters of a wide range of Stainless Steel 317L Butt Weld Pipe Fittings. Stainless Steel 317l contains higher chromium and low carbon content. Lower carbon means less chromium carbide precipitation due to welding.

It is applicable in various applications like car headers, machinery parts, screws and also food handling equipment. We offer these DIN 1.4301 Stainless Steel Butt Weld Fittings in different forms like Tees, Reducers, Cross, Stub Bends, Elbow and End caps. SS UNS S30400 Butt Weld Pipe Elbow execute excellent forming and welding properties. This type of steel also shows excellent oxidation resistant properties.

Superior Corrosion Resistance

SS 317L buttweld fittings offer exceptional protection against acids, chlorides, and sulfur compounds. This makes them highly suitable for industries facing harsh environments like chemical processing and oil & gas. The material's nickel and molybdenum content enhances durability, reducing maintenance needs and extending service life even in aggressive fluid transport systems.

Precision Manufacturing and Testing

Manufactured through seamless or welded processes, these fittings undergo rigorous hydrostatic, PMI, and NDT testing based on client requests. End preparation involves precisely beveled edges to facilitate strong, leak-free welds. The fittings are finished with smooth, burr-free surfaces and receive pickling and passivation treatments to ensure optimal metallurgical performance and longevity.

Versatile Applications and Design

Available in elbows, tees, reducers, caps, and stub ends-with outer diameters ranging from 1/2 to 24 inches-SS 317L buttweld fittings accommodate multiple pipeline configurations. Their robust design supports rated pressures from Class 150# to 2500#, and they are suitable for temperatures between -196C and 870C, making them ideal for critical process, power plant, and industrial applications.

FAQ's of SS 317L BUTTWELD FITTINGS:

Q: How does SS 317L buttweld fittings enhance corrosion resistance in industrial applications?

A: SS 317L buttweld fittings are made with elevated nickel (11-15%) and molybdenum (3-4%) content, offering superior resistance to acids, chlorides, and sulfur compounds. This ensures durability and extended service life in corrosive environments found in chemical, petrochemical, and oil & gas industries.Q: What manufacturing processes are used for SS 317L buttweld fittings?

A: These fittings are produced using both seamless and welded techniques. Each fitting is finished with smooth, burr-free surfaces and beveled ends to support robust, metal-to-metal weld connections. Surface treatments such as pickling and passivation further improve corrosion resistance and cleanliness.Q: Where are SS 317L buttweld fittings typically utilized?

A: They are widely used in pipeline systems across chemical processing, oil & gas, petrochemical plants, and power generation sectors. Their excellent tolerance for high pressures, variable temperatures, and aggressive media makes them suitable for critical fluid transfer applications.Q: What types of testing are conducted on SS 317L buttweld fittings?

A: Comprehensive tests, including hydrostatic testing, Positive Material Identification (PMI), and non-destructive testing (NDT), are performed as per customer requests and standards. These ensure the fittings' integrity, performance, and compliance with ASTM A403/ASME SA403 specifications.Q: When and how can SS 317L buttweld fittings be procured?

A: SS 317L buttweld fittings are available in ready stock or can be manufactured as per order requirements. Export-quality packaging is provided using wooden cases or pallets to maintain product safety during transport to domestic or international project sites.Q: What benefits do beveled ends provide in SS 317L buttweld fittings?

A: Beveled ends enhance welding precision, allowing for strong and leak-proof metal-to-metal joints. This design minimizes welding defects, supports consistent pipeline integrity, and makes installation easier and safer for industrial piping systems.Q: Can SS 317L buttweld fittings be customized for size and thickness?

A: Yes, fittings can be custom ordered with various diameters (12.7 mm to 609.6 mm) and thicknesses (SCH 10, SCH 40, SCH 80, or others as required), accommodating unique pipeline designs and ensuring compatibility with specific process requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese