- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

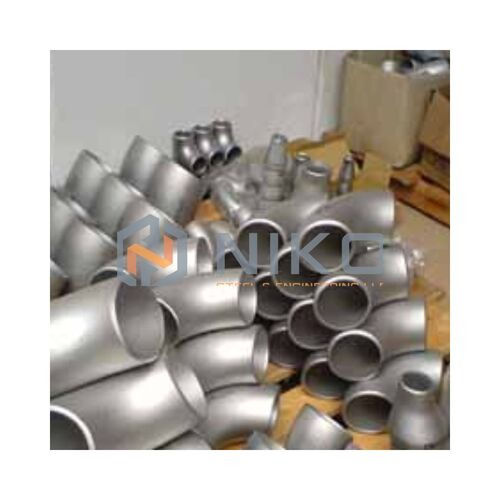

Socket Weld Pipe Fittings

160.00 - 190.00 INR/Kilograms

Product Details:

- Flexibility Rigid

- Sealing Type Metal to Metal / Welded Sealing

- Tolerance 0.1 mm

- Bend Radius As per fitting type (Elbow: Short/Long)

- Yield Strength Minimum 205 MPa

- Tensile Strength Minimum 485 MPa

- Connection Type Socket Welded

- Click to view more

X

Socket Weld Pipe Fittings Price And Quantity

- 20 Kilograms

- 160.00 - 190.00 INR/Kilograms

- Forged / Machined

- Plain End / Beveled End

- Fitting Grade, Size, Schedule, Heat No.

- 100% Dimension and Pressure Tested

- Solution Annealed (for SS)

- EN 10204 3.1, ISO 9001:2015

- Carton / Wooden Box Packing

Socket Weld Pipe Fittings Product Specifications

- Sch 40 / Sch 80 / Sch 160 / XXS

- Socket Weld

- Socket Weld Pipe Fittings

- ASTM A182 F304 / F316 / A105 / F11 / F22 etc.

- 2000 lbs, 3000 lbs, 6000 lbs, 9000 lbs

- Socket Welded

- 1/8 to 4 (DN6 to DN100)

- Metallic / Silver / Black

- Minimum 485 MPa

- Pipeline Connection, Industrial Fitting

- Minimum 205 MPa

- 0.1 mm

- Metal to Metal / Welded Sealing

- Round

- As per Standard / Requirement

- Pickled, Sand Blasted, Polished, Galvanized

- Elbow, Tee, Coupling, Union, Cross, Cap, Reducer

- Stainless Steel / Carbon Steel / Alloy Steel

- As per fitting type (Elbow: Short/Long)

- Rigid

- Oil & Gas, Petrochemical, Chemical, Power Plant, Water Treatment

- Forged / Machined

- Plain End / Beveled End

- Fitting Grade, Size, Schedule, Heat No.

- 100% Dimension and Pressure Tested

- Solution Annealed (for SS)

- EN 10204 3.1, ISO 9001:2015

- Carton / Wooden Box Packing

Socket Weld Pipe Fittings Trade Information

- 1 Kilograms Per Day

- 1 Days

Product Description

With our consistent endeavors in this domain, we are looked upon as a prime supplier and exporter of a wide array of high quality Socket Weld Pipe Fittings. These fittings are precisely manufactured at our vendors production unit by utilizing the high end quality materials in adherence with the industrial quality norms. To meet with the requirements of our wide client base, we offer Socket Weld Pipe Fittings in distinguished sizes, diameters and specifications.

Features of Socket Weld Pipe Fittings:

- Impeccable finish

- Dimension precision

- Corrosion resistant

Socket Weld Pipe Fittings Technical Specification:

|

NOM BORE |

PIPE O.D. |

3000 LBS. |

COMMON FACTOR |

6000 LBS. |

|||||||||||||||

| A max. |

B max. |

K |

J |

L |

M |

N |

P |

Q |

C max. |

D max. |

O min. |

O max. |

A |

B |

M |

K |

N |

||

|

1/8 |

10.3 |

22 |

18.5 |

26 |

16 |

40 |

17.3 |

32 |

17.5 |

10 |

10.7 |

10 |

5 |

8 |

22 |

22 |

20 |

25 |

46 |

|

1/4 |

13.7 |

22 |

22 |

26 |

18 |

43 |

21.2 |

32 |

17.5 |

10 |

14.1 |

10 |

5 |

8 |

27 |

25 |

24 |

25 |

51 |

|

3/8 |

17.2 |

25 |

25 |

26 |

19 |

48 |

25.4 |

36 |

19 |

10 |

17.6 |

10 |

3 |

9 |

27 |

28 |

28 |

26 |

60 |

|

1/2 |

21.3 |

27 |

32 |

30 |

21 |

51 |

31 |

43 |

22 |

10 |

21.7 |

10 |

6 |

13 |

31 |

34 |

34 |

31 |

72 |

|

3/4 |

26.7 |

34 |

38 |

36 |

24 |

57 |

37 |

50 |

25 |

13 |

27 |

13 |

6 |

13 |

37 |

42 |

41 |

35 |

80 |

|

1 |

33.4 |

37 |

46 |

40 |

25 |

64 |

45.2 |

60 |

27 |

13 |

33.8 |

13 |

9 |

17 |

42 |

50 |

50 |

40 |

94 |

|

1 1/4 |

42.2 |

42 |

56 |

40 |

29 |

70 |

55 |

70 |

30 |

13 |

42.6 |

13 |

9 |

17 |

47 |

59 |

58 |

41 |

100 |

|

1 1/2 |

48.3 |

47 |

62 |

40 |

30 |

79 |

61.4 |

78 |

32 |

13 |

48.7 |

13 |

9 |

17 |

53 |

67 |

66 |

43 |

122 |

|

2 |

60.3 |

56 |

75 |

52 |

37 |

89 |

75 |

95 |

38 |

13 |

612 |

16 |

15 |

23 |

59 |

84 |

83 |

55 |

|

|

2 1/2 |

73.02 |

60 |

92 |

52 |

48 |

114 |

91.3 |

125 |

38 |

16 |

73.8 |

16 |

14 |

24 |

|

102 |

|

56 |

|

|

3 |

89 |

76 |

110 |

52 |

51 |

127 |

108.8 |

140 |

44 |

16 |

89.8 |

16 |

14 |

24 |

|

121 |

|

58 |

|

|

4 |

114.50 |

88 |

137 |

58 |

|

150 |

136.9 |

|

48 |

19 |

115.5 |

19 |

14 |

24 |

|

152 |

|

64 |

|

|

NOM BORE |

PIPE O.D. |

3000 L.B.S. |

COMMON FACTORS |

6000 L.B.S. |

|||||||||||||||

|

A |

B |

C |

G |

H |

K |

D |

E |

F |

I |

J |

L |

A |

B |

C |

G |

H |

K |

||

|

1/8 |

10.3 |

21 |

22 |

17 |

32 |

16 |

19 |

11 |

10 |

40 |

0 |

3 |

0 |

25 |

25 |

19 |

32 |

22 |

- |

|

1/4 |

13.7 |

25 |

25 |

19 |

35 |

19 |

25 |

13 |

11 |

43 |

3 |

3 |

32 |

29 |

33 |

22 |

35 |

25 |

27 |

|

3/8 |

17.2 |

29 |

33 |

22 |

38 |

22 |

25 |

1 |

7.5 |

13 |

43 |

4 |

3 |

33 |

33 |

33 |

25 |

33 |

32 |

|

1/2 |

21.3 |

33 |

38 |

25 |

48 |

29 |

32 |

22 |

15 |

51 |

5 |

3 |

43 |

33 |

43 |

29 |

43 |

33 |

33 |

|

3/4 |

26.7 |

38 |

46 |

29 |

51 |

35 |

37 |

27 |

16 |

57 |

3 |

10 |

51 |

44 |

53 |

33 |

51 |

44 |

33 |

|

1 |

33.4 |

44 |

56 |

33 |

60 |

44 |

41 |

35 |

19 |

54 |

3 |

10 |

so |

51 |

52 |

35 |

30 |

57 |

43 |

|

1 1/4 |

42.2 |

51 |

62 |

35 |

67 |

57 |

44 |

44.5 |

21 |

70 |

7 |

14 |

72 |

30 |

75 |

43 |

37 |

34 |

43 |

|

1 1/2 |

48.3 |

60 |

75 |

43 |

79 |

64 |

44 |

51 |

21 |

79 |

3 |

13 |

so |

34 |

34 |

44 |

79 |

73 |

43 |

|

2 |

60.3 |

64 |

84 |

45 |

86 |

76 |

48 |

33.5 |

22 |

33 |

9 |

17 |

94 |

33 |

102 |

52 |

33 |

92 |

51 |

|

2 1/2 |

73.02 |

83 |

102 |

52 |

92 |

92 |

60 |

73 |

27 |

113 |

10 |

21 |

122 |

95 |

121 |

34 |

92 |

103 |

34 |

|

3 |

89.0 |

95 |

121 |

64 |

108 |

108 |

65 |

39 |

29 |

121 |

10 |

35 |

140 |

103 |

143 |

79 |

103 |

127 |

33 |

|

4 |

114.5 |

114 |

152 |

79 |

121 |

140 |

68 |

117.5 |

32 |

150 |

13 |

25 |

130 |

114 |

152 |

79 |

121 |

159 |

75 |

Comprehensive Quality Assurance

Each socket weld pipe fitting undergoes rigorous 100% dimensional and pressure testing to guarantee compliance with international standards. The fittings are clearly marked with grade, size, schedule, and heat number for complete traceability, meeting certification requirements such as EN 10204 3.1 and ISO 9001:2015. Carefully packaged in cartons or wooden boxes, these products arrive safe and ready for use.

Versatile Material and Design Options

Choose from a broad selection of materials including ASTM A182 F304, F316, A105, F11, F22, and more. Available in multiple thickness schedules (SCH 40, SCH 80, SCH 160, XXS), surface treatments, and end types (plain or beveled), our fittings suit diverse operational needs. Their robust construction ensures reliability at rated pressures ranging from 2000 lbs up to 9000 lbs, with strict tolerance control (0.1 mm) for precision installations.

Reliable Solutions for Critical Infrastructure

Socket weld fittings are engineered for enduring performance in pipeline connection and industrial fitting scenarios. Their metal-to-metal or welded sealing ensures leak-proof joins, suitable for rigid setup in oil & gas, petrochemical, chemical, power plant, and water treatment industries. With high tensile and yield strengths, these fittings withstand extreme conditions and ensure long service life.

FAQs of Socket Weld Pipe Fittings:

Q: How are socket weld pipe fittings manufactured and tested for quality?

A: Socket weld pipe fittings are produced using forging or machining techniques, which provide excellent strength and dimensional accuracy. Each fitting undergoes 100% dimensional and pressure testing in accordance with industry standards, ensuring reliable and leak-free performance. Additionally, heat treatment such as solution annealing is applied for stainless steel variants, further enhancing durability.Q: What applications are these fittings suitable for, and why are they preferred?

A: These fittings are ideal for pipeline connections across oil & gas, petrochemical, chemical, power plant, and water treatment sectors due to their robust design, high-pressure capabilities, and precise tolerances. Their metal-to-metal or welded sealing provides leak-proof joins, making them particularly preferred for critical, high-pressure environments.Q: When should I choose plain end versus beveled end socket weld fittings?

A: Plain end fittings are commonly used for straightforward socket weld connections, while beveled end options are suitable where additional weld penetration is required. Your choice depends on welding requirements and the specifications of the piping project.Q: Where are these socket weld pipe fittings most commonly installed?

A: They are widely installed in industrial settings such as refineries, chemical plants, power generation facilities, and water treatment operations, where secure, high-pressure connections are a necessity.Q: What is the process for marking, packaging, and certification of these fittings?

A: Each fitting is clearly marked with its grade, size, schedule, heat number, and other relevant data for traceability. After stringent inspection, fittings are securely packed in cartons or wooden boxes. Certification is provided as per EN 10204 3.1 and the company is ISO 9001:2015 accredited, ensuring adherence to international quality standards.Q: How does the choice of material and surface finish affect performance and usage?

A: Material selectionwhether stainless steel, carbon steel, or alloy steelimpacts corrosion resistance, temperature capability, and mechanical strength. Surface finishes like pickling, sand blasting, polishing, and galvanizing provide added protection against corrosion and enhance overall lifespan, making them suitable for a range of industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese