- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

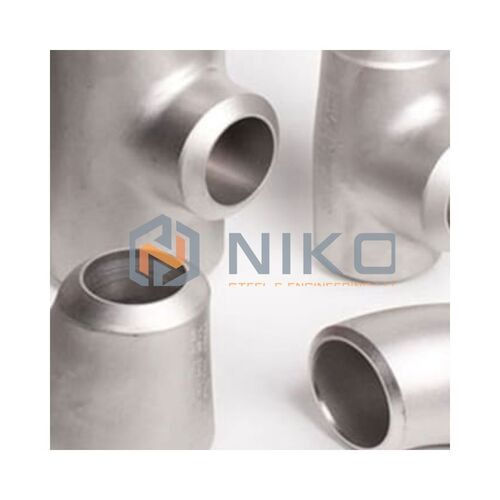

Seamless Butt Weld Fittings

160.00 - 190.00 INR/Kilograms

Product Details:

- Bend Radius 1D, 1.5D, 2D, Custom

- Tensile Strength 415620 MPa (Depending on Material Grade)

- Connection Type Welded

- Tolerance 0.1 mm to 0.5 mm

- Flexibility Rigid

- Yield Strength 205485 MPa (Depending on Material Grade)

- Coating Type Oiled / Black Paint / Rust Proof Coating

- Click to view more

X

Seamless Butt Weld Fittings Price And Quantity

- 20 Kilograms

- 160.00 - 190.00 INR/Kilograms

Seamless Butt Weld Fittings Product Specifications

- Welded

- 304 / 304L / 316 / 316L / 321 / 347 / 310S / A234 WPB / WP11 / WP22

- 0.1 mm to 0.5 mm

- As per specification or drawing

- Elbow, Tee, Reducer, Cap, Cross

- Butt Weld

- 415620 MPa (Depending on Material Grade)

- 1/2 inch to 48 inch (DN15DN1200)

- Seamless Butt Weld Fittings

- ASTM A403 / ASME B16.9 / DIN / JIS

- Polished

- 205485 MPa (Depending on Material Grade)

- Oiled / Black Paint / Rust Proof Coating

- Rigid

- Metallic Silver / Black

- Round

- Pipe Fitting / Fluid Transfer

- SCH10S, SCH20, SCH40, SCH80, SCH160, XXS

- Oil & Gas, Petrochemical, Power Plants, Ship Building, Water Treatment, Chemical Industries

- 1D, 1.5D, 2D, Custom

- Up to 6000 PSI

- Stainless Steel / Carbon Steel / Alloy Steel

Seamless Butt Weld Fittings Trade Information

- 1 Kilograms Per Day

- 1 Days

Product Description

We are counted amongst the profound manufacturers and exporters, offering the best quality array of Seamless Butt Weld Fittings. These fittings are manufactured under the guidance of our deft professionals by making use of quality approved materials. Due to their easy fitting and rust proof nature, these are widely demanded for fitting in pipe. In addition, our clients can avail these Seamless Butt Weld Fittings in numerous specifications at affordable prices.

Features of Seamless Butt Weld Fittings:

- High strength

- Easy installation

- Accurate dimensional

Exceptional Corrosion Resistance

Our seamless butt weld fittings are primarily crafted from stainless steel, ensuring outstanding resistance to corrosion. This makes them particularly suitable for demanding environments such as chemical processing, water treatment, and marine applications. The polished surface treatment further enhances durability and longevity in corrosive conditions.

Comprehensive Quality Assurance

Each fitting undergoes stringent non-destructive testsultrasonic, radiography, or dye penetrantas well as hydrostatic pressure testing (1.5 rated pressure) to guarantee reliability and safety. Test certificates (EN 10204 3.1/3.2) are systematically provided with each order, assuring traceability and compliance with international standards.

Versatile Specifications and Applications

With a wide range of diameters (1/2 inch to 48 inch), wall thicknesses (SCH10S to XXS), and shapes (elbow, tee, reducer, etc.), these fittings are customized to meet unique project requirements. Designed for butt welding, they serve multiple sectors including oil & gas, power plants, shipbuilding, and petrochemicals, facilitating smooth and leak-free fluid transfer.

FAQs of Seamless Butt Weld Fittings:

Q: How are seamless butt weld fittings produced?

A: These fittings are manufactured using either hot formed or cold formed production processes. Hot forming involves heating the material and shaping it, while cold forming is performed at lower temperatures for enhanced dimensional accuracy and mechanical properties.Q: What makes these fittings suitable for corrosive environments?

A: Seamless butt weld fittings made from stainless steel offer excellent resistance to corrosion, making them ideal for chemical, water treatment, and offshore applications. The polished surface treatment further improves their durability against aggressive substances.Q: When are test certificates and non-destructive tests provided for these fittings?

A: Test certificates according to EN 10204 3.1/3.2 are issued with every order. Non-destructive testingsuch as ultrasonic, radiography, and dye penetrant testingis performed during quality control to ensure conformance and safety before dispatch.Q: Where can seamless butt weld fittings be used?

A: These fittings are widely employed in oil & gas, petrochemical, power plants, shipbuilding, water treatment, and various chemical industries for fluid transfer and pipeline connections due to their robust design and versatility.Q: What is the process for ordering these fittings with custom specifications?

A: Customers can specify details such as material grade, wall thickness, bend radius, length, and coating type when placing an order. Minimum order quantity is flexible and determined according to the customers requirements.Q: What benefits do these fittings offer over other connection types?

A: Butt weld fittings provide a seamless and rigid connection, which minimizes leakage risk and ensures high-pressure capabilities, tensile and yield strength, and extended service life in demanding applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese