- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

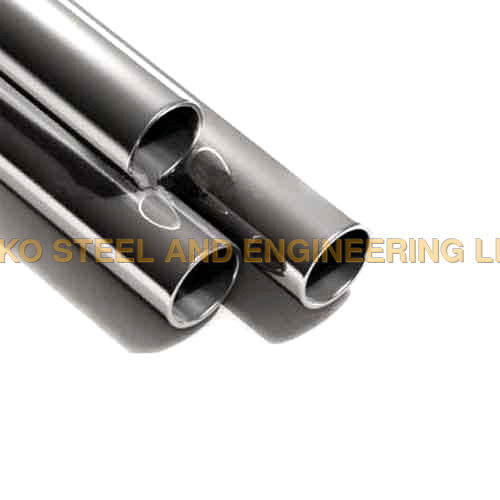

Monel 400 Seamless Pipe

160.00 - 190.00 INR

Product Details:

- Thread Type NPT/BSPT (for threaded ends)

- Coating Type No External Coating (as supplied)

- Flexibility Rigid

- Temperature Range -29C to +550C

- Sealing Type Metal-to-Metal

- Tensile Strength 480 MPa min

- Yield Strength 170 MPa min

- Click to view more

X

Monel 400 Seamless Pipe Price And Quantity

- 20 Kilograms

- 160.00 - 190.00 INR

- Plastic Caps on Pipe Ends

- Easily Weldable & Fabricable

- 8.8 g/cm

- Slightly Magnetic at Room Temperature

- Wooden Cases, Bundles, or as Required

- 1300C 1350C

- 30% min

- Rockwell B75-90

- Excellent in Seawater and Chemical Environments

- As per Requirement

Monel 400 Seamless Pipe Product Specifications

- Rigid

- Up to 6000 PSI (based on size & wall thickness)

- -29C to +550C

- Monel 400 (Nickel-Copper Alloy)

- No External Coating (as supplied)

- Chemical Processing, Marine, Oil & Gas, Heat Exchangers

- NPT/BSPT (for threaded ends)

- Monel 400 (UNS N04400)

- Cylindrical

- Silver / Metallic Grey

- 6 mm to 273 mm

- Single Random, Double Random, or Custom

- As per manufacturing standards

- 0.5 mm

- 6 mm to 273 mm

- Plain, Beveled, Threaded Ends

- Round

- Polished

- Seamless Pipe

- 170 MPa min

- Welded / Plain End

- 1 mm to 10 mm

- 480 MPa min

- Corrosion Resistant Applications

- ASTM B165 / ASME SB165

- Metal-to-Metal

- Plastic Caps on Pipe Ends

- Easily Weldable & Fabricable

- 8.8 g/cm

- Slightly Magnetic at Room Temperature

- Wooden Cases, Bundles, or as Required

- 1300C 1350C

- 30% min

- Rockwell B75-90

- Excellent in Seawater and Chemical Environments

- As per Requirement

Monel 400 Seamless Pipe Trade Information

- 1 Kilograms Per Day

- 1 Days

Product Description

Specification of Monel 400 Seamless Pipe:

- Stainless Steel : 304/304L, 316/316L/316Ti, 321, 310/310S, 317/317L, 347, etc.

- Copper, Brass, Aluminium, Nast Alloy, Titanium, Monel, Inconel, Nickel, etc.

- Duplex Steel : UNS 31083, UNS 32205, UNS 32750, UNS 32760

- Alloy Steel: P1, P5, P9, P11, P12, P22, P23, P91 Carbon Steel, Mild Steel

- Specification : ASTM, AISI, ASME, DIN, UNS etc.

Size: 1/8" NB, Upto 48" NB. in Sch 5.10, 40, 80,160, XS, XXS

Types:

- Forms : ERW & Seamless

- Shapes: Round, Square, Rectangular, Triangular, Oval

Durability and Corrosion Resistance

Monel 400 seamless pipes exhibit outstanding durability and resistance to a variety of corrosive environments, especially seawater and chemical processing media. Their high nickel and copper content ensures a long service life even under challenging conditions, making them highly suitable for marine and offshore applications.

Customization and Standards

These pipes are produced according to globally recognized standards such as ASTM B165 and ASME SB165. Customers can select from a range of diameters (6 mm to 273 mm), thicknesses (1 mm to 10 mm), and lengths (single random, double random, or custom). Options for end connections include plain, beveled, or threaded (NPT/BSPT) ends.

Applications Across Industries

Due to their strength and corrosion resistance, Monel 400 seamless pipes are extensively used in marine industries, oil & gas facilities, chemical processing plants, and for heat exchangers. Their resistance to high pressures (up to 6000 PSI) and temperatures (-29C to +550C) make them versatile for demanding operational environments.

FAQs of Monel 400 Seamless Pipe:

Q: How is Monel 400 seamless pipe fabricated?

A: Monel 400 seamless pipe is fabricated using specialized processes that allow for easy welding and forming. It is supplied in cylindrical sections, often with welded, plain, or threaded ends as needed, and can be customized in terms of diameter, thickness, and length.Q: What makes Monel 400 seamless pipe highly corrosion resistant?

A: The high nickel (Ni) and copper (Cu) composition of Monel 400 provides excellent resistance to corrosion, particularly in seawater, acidic, and chemical environments. This makes the pipe ideal for marine and chemical processing applications.Q: When should Monel 400 seamless pipe be used over other materials?

A: Monel 400 seamless pipe should be chosen when superior resistance to corrosion, especially in marine or chemical settings, is required. It is also preferred when high strength, good ductility, and excellent thermal stability are important for the application.Q: Where are Monel 400 seamless pipes commonly installed?

A: These pipes are widely used in marine industries, offshore platforms, chemical processing units, oil and gas refineries, and heat exchangers due to their exceptional durability and resistance to harsh environments.Q: What are the benefits of using Monel 400 seamless pipe in engineering projects?

A: Benefits include high resistance to corrosion and stress cracking, excellent mechanical properties at both low and high temperatures, a long service life, and ease of fabrication and welding, ensuring reliable performance in critical applications.Q: How are Monel 400 seamless pipes typically packed and protected during shipping?

A: For safe and secure transport, pipes are packed in wooden cases or bundles as per customer requirements, with plastic caps fitted on the ends to protect against physical damage and contamination.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese