- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

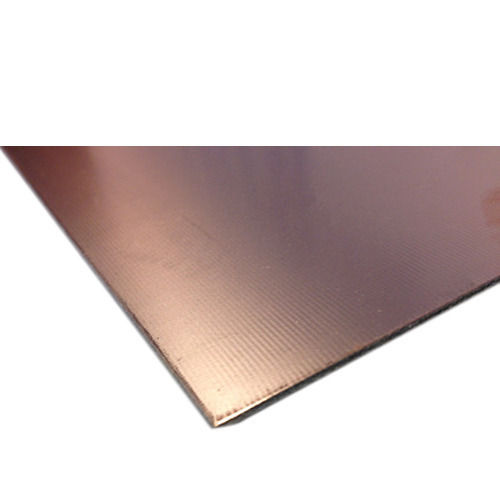

Copper clad laminated sheets

160 INR/Kilograms

Product Details:

- Recyclable Yes

- Corrosion Resistant Yes, copper surface is corrosion resistant to certain extent

- Hardness HRB 80 (Copper surface)

- Product Form Sheet

- Coating Type Electrolytic copper clad

- Size Standard: 1200 mm x 900 mm, Custom sizes available

- Heat Resistance Yes

- Click to view more

X

Copper clad laminated sheets Price And Quantity

- 100 Kilograms

- 160.00 - 190.00 INR/Kilograms

- 160 INR/Kilograms

- Anti-oxidation coating (optional)

- -40C to +130C

- Excellent

- Epoxy resin with woven fiberglass

- Cut, non-burred

- 1.85 g/cm

- High

- Yes

- 18 kV/mm

- High-pressure heat bonded

- >1 x 10^6 M

- Yes, meets UL94-V0 standard

- <0.02%

- 35 m (standard)

Copper clad laminated sheets Product Specifications

- PCB manufacturing, prototyping, circuit development

- Matte/Smooth copper clad

- Copper Clad Laminated Sheet

- HRB 80 (Copper surface)

- Smooth copper finish

- FR-4, CEM-1

- Copper foil laminated onto epoxy resin/fiberglass substrate

- Sheet

- Used in PCB manufacturing, electrical insulation, and electronic equipment.

- Rectangular

- 1200 mm x 900 mm x 1.6 mm

- Yes

- Approx. 2.8 kg per sheet

- Copper (top surface), light green or off-white substrate

- Copper: ~18%, Resin/Fiberglass: ~82%

- 340 MPa (approx)

- 1.6 mm

- Yes, copper surface is corrosion resistant to certain extent

- Industrial Electronic Grade

- Standard: 1200 mm x 900 mm, Custom sizes available

- Electrolytic copper clad

- Yes

- Anti-oxidation coating (optional)

- -40C to +130C

- Excellent

- Epoxy resin with woven fiberglass

- Cut, non-burred

- 1.85 g/cm

- High

- Yes

- 18 kV/mm

- High-pressure heat bonded

- >1 x 10^6 M

- Yes, meets UL94-V0 standard

- <0.02%

- 35 m (standard)

Copper clad laminated sheets Trade Information

- 100 Kilograms Per Day

- 1 Week

Product Description

Copper clad laminated sheets

Clad in Copper Laminate sheets are produced by pressing membranes of filler material impregnated with specially formulated phenolic resins under high pressure and heat and then bonding the layers together with electro-deposited copper foil to form a thermoset composite material. Provides good electrical, mechanical, moisture, and heat resistant qualities and can be used for hot and cold punching applications. Environmental elements such as humidity, temperature, corrosive atmosphere, and other factors impact the mechanical and electrical properties of copper-clad laminated sheets, among other things.

Superior Flame Retardancy & Safety

Designed to meet UL94-V0 flame-retardant standards, these copper clad laminated sheets are exceptionally safe for use in environments that demand high fire resistance. Their composition minimizes risk during operation, making them an optimal choice for manufacturers prioritizing both electronic performance and user safety.

Robust Construction & Reliable Performance

Each sheet features a standard 35 m copper finish bonded to an industrial-grade epoxy resin with fiberglass, ensuring excellent dielectric strength and outstanding electrical insulation. The material structure supports high tensile strength and reliability, critical in PCB manufacturing and high-performance electronic assemblies.

Multi-Industry Applications & Customization

Perfectly suited for PCB fabrication, electrical insulation, and prototyping, these sheets are widely used in electronic industries across India and beyond. With custom sizes available, manufacturers can tailor sheet dimensions for specialized requirements, enabling greater flexibility and efficiency in production processes.

FAQs of Copper clad laminated sheets:

Q: How are these copper clad laminated sheets manufactured for optimal quality?

A: The sheets are manufactured using a high-pressure heat bonding process, which firmly laminates electrolytic copper foil onto an epoxy resin base reinforced with woven fiberglass. This ensures consistent thickness, high bonding strength, and a smooth, burr-free edge finish.Q: What are the main benefits of using these sheets in PCB manufacturing?

A: These sheets provide high dielectric strength, moisture and corrosion resistance, and excellent solderability, which are essential for ensuring durability and reliable performance in printed circuit board (PCB) applications. Their flame-retardant nature further enhances device safety.Q: Where are copper clad laminated sheets commonly applied?

A: These sheets are primarily used in the fabrication of PCBs for electronic devices, circuit prototyping, electrical insulation, and various electronic equipment. Their quality and features meet the rigorous demands of industrial, commercial, and consumer electronics.Q: What makes these sheets suitable for high-moisture environments?

A: Featuring moisture absorption under 0.02% and high insulation resistance, the sheets perform reliably even in humid conditions. The epoxy resin and fiberglass substrate also contribute to their high moisture and heat resistance.Q: When should I consider requesting custom dimensions for these sheets?

A: Custom dimensions are ideal when standard 1200 x 900 mm sheets do not fit your specific project or production line requirements. Custom sizing optimizes material utilization and reduces manufacturing waste during PCB fabrication or electrical assembly.Q: What process ensures the copper surface remains oxidation-resistant?

A: An optional anti-oxidation coating can be applied to the copper surface. This surface treatment helps prevent oxidation and corrosion, extending the sheets shelf life and improving long-term reliability in electronic assemblies.Q: Are these copper clad laminated sheets compliant with environmental standards?

A: Yes, they comply with RoHS regulations, minimizing hazardous substances in their construction. Additionally, these sheets are recyclable, supporting sustainable and environmentally responsible manufacturing practices.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese