- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

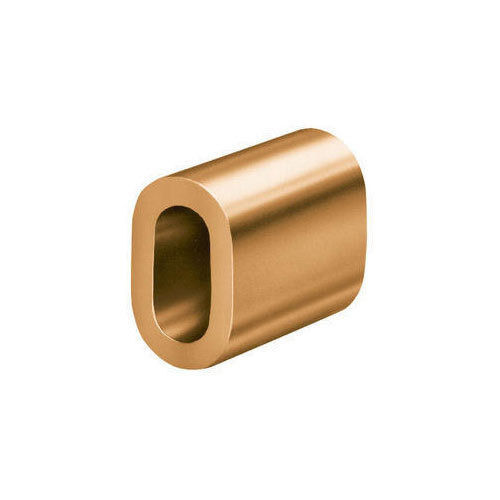

Copper alloy olets

160 INR/Kilograms

Product Details:

- Corrosion Resistant Excellent, especially to seawater and industrial chemicals

- Tensile Strength Up to 340 MPa (varies with grade)

- Heat Resistance Yes

- Coating Type Usually uncoated, but optional coating available

- Hardness 60-110 HB (dependent on grade)

- Size Standard & customized sizes

- Product Form Forged or Cast Olet

- Click to view more

X

Copper alloy olets Price And Quantity

- 100 Kilograms

- 160.00 - 190.00 INR/Kilograms

- 160 INR/Kilograms

- Plain / Beveled / Threaded

- -196°C to +400°C depending on alloy

- ISO, ASTM, ASME standards

- Long-lasting under optimal operating conditions

- Forged or machined

- Class 3000/6000/9000 as per design

- Export standard sea-worthy packaging

- Cleaned, deburred, ready for installation

- Welded (Socket Weld, Threaded, Butt Weld)

- Typically 2-4 weeks for standard sizes

Copper alloy olets Product Specifications

- Copper 63-90%, Nickel/Other Alloying Elements

- Piping, Plumbing, Chemical Processing, Oil & Gas

- Varies as per size and specification

- Round, as per olet branch design

- Yes

- 1/2 to 36 nominal branch size

- C70600, C71500, C27200, etc.

- Forged or Cast Olet

- Outlet Fittings (Olet)

- Customizable as per requirement

- Branch connections, piping reinforcement

- Standard & customized sizes

- 60-110 HB (dependent on grade)

- As per standard or customer specification

- Non-Ferrous Metal (Copper Alloy)

- Usually uncoated, but optional coating available

- ASTM B62, ASTM B466, ASME SB62

- Yes

- Copper-Nickel alloys (CuNi10Fe1Mn, CuNi30Mn1Fe) and Brass

- Up to 340 MPa (varies with grade)

- Reddish Gold / Coppery

- Standard Copper Alloy Grades

- Copper Alloy Olets

- Excellent, especially to seawater and industrial chemicals

- Polished, Bare, or as per requirement

- Smooth/Polished Finish or as specified

- Plain / Beveled / Threaded

- -196°C to +400°C depending on alloy

- ISO, ASTM, ASME standards

- Long-lasting under optimal operating conditions

- Forged or machined

- Class 3000/6000/9000 as per design

- Export standard sea-worthy packaging

- Cleaned, deburred, ready for installation

- Welded (Socket Weld, Threaded, Butt Weld)

- Typically 2-4 weeks for standard sizes

Copper alloy olets Trade Information

- 100 Kilograms Per Day

- 1 Week

Product Description

Copper alloy olets

NIKO STEEL AND ENGINEERING LLP is a well-known manufacturer and trader that provides a wide range of copper alloy olets resistant to erosion in various environments. The company was established in the year 2000. These fittings are made of single-stage solid-solution steel, which gives greater resistance to a wide range of corrosive environments over a temperature range of sub-zero to 800 degrees Fahrenheit. These materials exhibit excellent strength and corrosion resistance in a wide range of media, including hydrofluoric acid, sulphuric acid, alkalis, and seawater. The copper alloy olets that are offered have excellent strength and endurance across a wide temperature range and great resistance to a wide range of corrosive conditions. The high strength and great erosion resistance of these olets allow them to be used in various settings.

PACKING:

We recognize the importance of packaging, particularly in international shipments, because the consignment must travel through many channels before reaching its final destination. As a result, we take great care in the packaging of our shipments.

Depending on the product, we package our items in a variety of methods. Our products are packaged in a variety of ways, including the following:

- Shrink-wrapped

- Boxes

- Pallets

- Crates

- Carton boxes

Versatile Forged and Machined Olets

Copper Alloy Olets are available in both forged and machined forms, offering flexibility to meet various engineering requirements. Each outlet fitting can be customized in size, thickness, and end typeplain, beveled, or threadedto suit diverse piping configurations. Their robust construction ensures a secure and durable branch connection, supporting a range of pressure ratings up to Class 9000.

Exceptional Corrosion and Heat Resistance

Designed from premium copper-nickel alloys and brass, these olets provide outstanding resistance to seawater, industrial chemicals, and high temperatures. Their excellent mechanical strength and smooth finish ensure longevity and minimal maintenance in harsh service conditions, making them an ideal choice for demanding industries needing reliable piping reinforcement.

Compliance and Quality Assurance

Every Copper Alloy Olet strictly adheres to international standards such as ISO, ASTM B62/B466, and ASME SB62. Manufactured under controlled processes, they undergo thorough cleaning and deburring, arriving installation-ready in export-standard packaging. This commitment to quality guarantees safety, reliability, and regulatory compliance for critical applications.

FAQs of Copper alloy olets:

Q: How are Copper Alloy Olets manufactured and what connection types are supported?

A: Copper Alloy Olets are either forged or machined to precise dimensions based on application needs. They are designed for welded connections, supporting Socket Weld, Threaded, and Butt Weld end types, ensuring compatibility with a variety of piping systems.Q: What standards and grades do these olets comply with?

A: These olets meet international standards such as ISO, ASTM B62/B466, and ASME SB62. Available grades include C70600, C71500, C27200, and other standard copper alloy grades, ensuring suitability for various industry requirements.Q: When can I expect delivery and are the sizes customizable?

A: Standard sizes are typically available within 24 weeks. Custom dimensionsincluding diameter, thickness, and lengthcan be manufactured as per your requirements, with lead times adjusted accordingly.Q: Where are Copper Alloy Olets commonly used?

A: They are widely used in applications including piping, plumbing, chemical processing, oil and gas, and other demanding environments where corrosion resistance and mechanical strength are essential.Q: What benefits do Copper Alloy Olets offer in service life and performance?

A: With excellent corrosion resistance, good heat stability, and robust mechanical properties, these olets ensure extended service life, reduced maintenance, and reliable performance under optimal operating conditions.Q: How should these olets be handled upon delivery?

A: Copper Alloy Olets are delivered cleaned, deburred, and packed in export standard sea-worthy packaging. They are installation-ready, minimizing on-site preparation time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese