- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

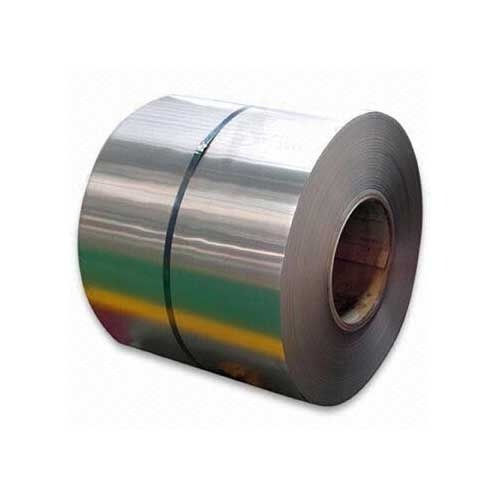

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

Continuous cast copper rods

160 INR/Kilograms

Product Details:

- Size 8 mm, 8-12 mm options

- Recyclable Yes

- Corrosion Resistant Yes, high corrosion resistance

- Product Form Rod (Coil form)

- Tensile Strength 205 MPa

- Material Composition % Copper 99.90%, Oxygen 0.04%

- Hardness 55-65 HV

- Click to view more

X

Continuous cast copper rods Price And Quantity

- 100 Kilograms

- 160 INR/Kilograms

- 160.00 - 190.00 INR/Kilograms

Continuous cast copper rods Product Specifications

- Copper (Cu) min. 99.90%

- 8 mm, 8-12 mm options

- ASTM B49 / IS 12444 / JIS H3100

- Yes

- Yes, high corrosion resistance

- Electrical conductors, cable industry, wires, magnet wire production, industrial electrical installations

- Polished, smooth

- Rod (Coil form)

- Conductor manufacturing, cable and wire drawing, electrical engineering applications

- 205 MPa

- Bright, smooth, free from surface defects

- ETP Grade (C11000)

- Copper 99.90%, Oxygen 0.04%

- Custom, typically supplied as coiled rods up to 3 tons per coil

- Approximately 2-3 tons per coil

- Round Rod

- 55-65 HV

- Not applicable (Copper product)

- Continuous Cast Copper Rods

- Standard 8 mm, available in 8-12 mm upon request

- Excellent heat resistance

- Reddish copper

- Electrolytic Tough Pitch Copper (ETP)

Continuous cast copper rods Trade Information

- 100 Kilograms Per Day

- 1 Week

Product Description

Continuous cast copper rods

Our continuous cast copper rods are manufactured per international quality standards. Because of its uniform structure and tiny grain size, it has exceptional drawability and abrasion resistance. It may be pulled to a wire at high speed, allowing for more efficient use of resources. Niko Steel and Engineering Limited is one of India's largest manufacturers of copper rods. In addition to power and communication cables, our rod line is also deemed suited for home wire, stripping for magnet wires, distribution and power transformers, and other applications. Because of their superior surface polish, they are appropriate for use in producing enameled, coated, and plated wires. All of our continuous cast copper rods are packaged in coil form wrapped in HDPE cover, wooden pallets, and then stretched wrapped on top of it to preserve their surface. Trucks, trains, and ships are used to transport goods to and from clients.

Superior Electrical Conductivity and Quality

Our continuous cast copper rods offer outstanding electrical conductivity ( 100% IACS) and exceptional elongation ( 35%), making them a reliable choice for demanding electrical and industrial applications. Produced under strict international standards, the rods maintain a polished, defect-free surface and are resistant to both corrosion and heat.

Versatile Applications Across Industries

Suitable for a multitude of uses, these copper rods find extensive application in electrical conductors, cable and wire manufacturing, magnet wire production, and various industrial electrical installations. Their high-purity ETP grade ensures performance longevity, making them a preferred material in the cable industry and electrical engineering sectors.

Customizable Dimensions and Secure Packaging

Our rods are typically supplied as coiled forms (23 tons per coil), with diameter options ranging from 8 mm to 12 mm to fit specific requirements. Packaging is customizable, using export-standard materials like plastic or steel banding for secure transportation. Orders are fulfilled within 24 weeks, ensuring timely delivery worldwide.

FAQs of Continuous cast copper rods:

Q: How are continuous cast copper rods manufactured?

A: These rods are produced using advanced continuous casting technology, where molten electrolytic tough pitch copper is solidified into a round rod form. This process ensures high purity, excellent surface finish, and superior mechanical properties such as high electrical conductivity and elongation.Q: What are the typical applications of these copper rods?

A: Continuous cast copper rods are primarily used for manufacturing electrical conductors, cables, wires, and magnet wires. They are also suitable for use in industrial electrical installations and electrical engineering projects where high conductivity and durability are essential.Q: When can I expect delivery after placing an order for copper rods?

A: Lead times for these copper rods are generally 24 weeks after order confirmation, ensuring a prompt and reliable supply for your production requirements.Q: Where can these copper rods be supplied or shipped?

A: As an exporter, importer, manufacturer, and supplier based in India, we provide these copper rods to domestic and international markets, meeting various industry standards for quality and consistency.Q: What customization options are available for coil size and packaging?

A: We offer customization in rod diameter (standard 8 mm, available up to 12 mm) and coil size (typically 23 tons per coil). Packaging can be adapted to customer preferences, utilizing standard export packing materials with plastic or steel banding and other requested specifications.Q: How does the use of ETP grade copper benefit electrical applications?

A: ETP (Electrolytic Tough Pitch) copper, with a minimum purity of 99.90%, provides superior electrical conductivity and ductility. This translates to efficient current transmission, increased durability, and a product that meets stringent industry requirements for electrical and electronic applications.Q: What environmental and compliance features do these copper rods offer?

A: Our copper rods are recyclable, RoHS compliant, and possess high heat and corrosion resistance. These properties ensure sustainability while providing safe and reliable performance in demanding operational environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese