- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

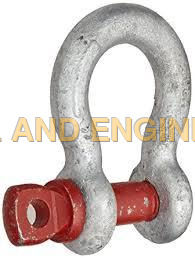

Carbon Steel Shackles

160 INR/Kilograms

Product Details:

- Heat Resistance Yes

- Material Composition % Carbon 0.25%-0.45%, Manganese 0.60%-1.20%, remainder Iron

- Corrosion Resistant Yes, with galvanized coating

- Diameter Up to 13mm (varies by model)

- Product Form Shackle

- Size Varies - typically 6mm, 8mm, 10mm, 13mm (as per user requirement)

- Coating Type Electro-galvanized or hot-dip galvanized

- Click to view more

X

Carbon Steel Shackles Price And Quantity

- 100 Kilograms

- 160.00 - 190.00 INR/Kilograms

- 160 INR/Kilograms

- Bulk packed or as per order requirements

- Up to 5 times the Working Load Limit (WLL)

- Store in dry conditions to prolong service life

- Screw pin or bolt-type nut & cotter

- -20C to +200C

- Meets CE, ISO, and relevant industry safety standards

- Varies by size, typically from 0.5 ton to 6 tons

- Supplied with matching pin/bolt

- Low; periodic inspection and lubrication recommended

- Zinc/chromate coating for enhanced protection

- Technical support available

- Safety factor 5:1 (typical industry standard)

- Available for size, finish, branding

- Suitable for crane, hoist, and lifting gear

- Batch number, load rating, and manufacturers mark stamped on body

Carbon Steel Shackles Product Specifications

- 120-180 HB

- Shackle / Hardware fitting

- Min. 400 MPa to 600 MPa

- Carbon, Manganese, Iron

- Electro-galvanized or hot-dip galvanized

- Varies; common size illustrated approx. 90mm x 60mm x 13mm (may vary as per model)

- Bow (anchor) / D-shape

- Yes

- Shackle

- Galvanized

- Silver (zinc coated)

- Varies - typically 6mm, 8mm, 10mm, 13mm (as per user requirement)

- Grade 40 / Grade 60 or equivalent

- Securing, lifting, fastening chains or wires

- Up to 13mm (varies by model)

- Lifting, rigging, marine, construction, material handling, industrial applications

- Galvanized, Hot-dip galvanized, or self color

- Grade 40/60 or as specified

- Up to 13mm (varies by size)

- Carbon Steel

- Carbon Steel Shackles

- Approx. 180g800g (depends on size)

- Yes

- Carbon 0.25%-0.45%, Manganese 0.60%-1.20%, remainder Iron

- Yes, with galvanized coating

- ASTM A36, EN 10277 or equivalent

- Bulk packed or as per order requirements

- Up to 5 times the Working Load Limit (WLL)

- Store in dry conditions to prolong service life

- Screw pin or bolt-type nut & cotter

- -20C to +200C

- Meets CE, ISO, and relevant industry safety standards

- Varies by size, typically from 0.5 ton to 6 tons

- Supplied with matching pin/bolt

- Low; periodic inspection and lubrication recommended

- Zinc/chromate coating for enhanced protection

- Technical support available

- Safety factor 5:1 (typical industry standard)

- Available for size, finish, branding

- Suitable for crane, hoist, and lifting gear

- Batch number, load rating, and manufacturers mark stamped on body

Carbon Steel Shackles Trade Information

- 100 Kilograms Per Day

- 1 Week

- All India

Product Description

Gaining immense appreciation from clients, we are successfully manufacturing and exporting an excellent range of Carbon Steel Shackles. These shackles are widely used in material handling equipments. Our highly experienced team uses best quality carbon steel for manufacturing these shackles in strict tandem with the industry standards. These Carbon Steel Shackles are subjected to stringent test procedures before the final dispatch in market.

Features of Carbon Steel Shackles:

- High tensile strength

- Corrosion resistant

- Durable quality

Reliable Strength and Safety

Each carbon steel shackle is engineered with a high safety factor of 5:1 and a breaking strength of up to five times the stated Working Load Limit (WLL). Stamped markings on the body detail load rating, batch number, and manufacturer identification, ensuring traceability and adherence to safety standards like CE and ISO.

Optimal Corrosion and Heat Resistance

Protected by electro-galvanized or hot-dip galvanized coatings, these shackles are highly resistant to rust and can be safely utilized in temperatures ranging from -20C to +200C. This makes them suitable for outdoor, marine, or industrial applications, enhancing longevity and reducing maintenance needs.

Customization & Support Services

Carbon steel shackles are available in various shapes (bow or D-shape), sizes (6mm to 13mm diameter), and finishes. Bulk or custom packaging is offered according to order. Technical support and after-sales service are provided, helping maximize safe and efficient usage.

FAQs of Carbon Steel Shackles:

Q: How do I select the correct carbon steel shackle for my lifting or rigging task?

A: Select a shackle by considering your required load capacity, pin type (screw pin or bolt-type), and the design factor. Always ensure the chosen models Working Load Limit (WLL) matches or exceeds the load you intend to lift. Refer to the stamped markings for load ratings and seek a shackle certified to CE, ISO, or relevant standards.Q: What maintenance is required for carbon steel shackles to ensure optimal performance?

A: While these shackles require low maintenance, periodic inspection for signs of wear, deformation, or corrosion is advised. Regular lubrication of moving parts and cleaning to remove debris will extend their service life, especially when used in harsh or marine environments.Q: When is it necessary to replace a carbon steel shackle?

A: Replace the shackle if you notice any signs of deformation, excessive corrosion, damaged threads, or if the load rating markings are no longer legible. Its crucial to adhere to scheduled inspections and follow industry safety protocols for replacement intervals, particularly after heavy use or impact events.Q: Where can carbon steel shackles be used effectively?

A: These shackles are suitable for use in a variety of environments including construction sites, shipyards, marine operations, warehouses, and industrial plants. They are designed for applications like securing chains, lifting loads with cranes and hoists, rigging, and general material handling.Q: What is the process for ordering customized carbon steel shackles?

A: To order customized shackles, specify your requirements for size, design (bow or D-shape), material grade, finish (galvanized or self-color), and branding preferences. Contact the manufacturer or supplier with your needs for technical guidance and to ensure compliance with safety standards.Q: How does the galvanized coating benefit the service life of these shackles?

A: The hot-dip or electro-galvanized coating provides enhanced rust and corrosion resistance, making the shackles suitable for use outdoors, in marine settings, or humid environments. This protection significantly prolongs their durability and reduces replacement frequency, providing better value and safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese