- मुखपृष्ठ

- कंपनी प्रोफाइल

-

आमची उत्पादने

- औद्योगिक बोल्ट

- अँकर फास्टनर्स

- औद्योगिक काजू

- औद्योगिक वॉशर्स

- सॉकेट स्क्रू

- मशीन स्क्रू

- स्व-टॅपिंग स्क्रू

- थ्रेडेड रॉड्स

- स्क्रू

- Flanges

- औद्योगिक हुक

- थ्रेडेड बार

- पाईप फिटिंग्ज

- ट्यूब फिटिंग्ज

- सीएनसी घटक आणि फॅब्रिकेशन

- सायफन ट्यूब्स

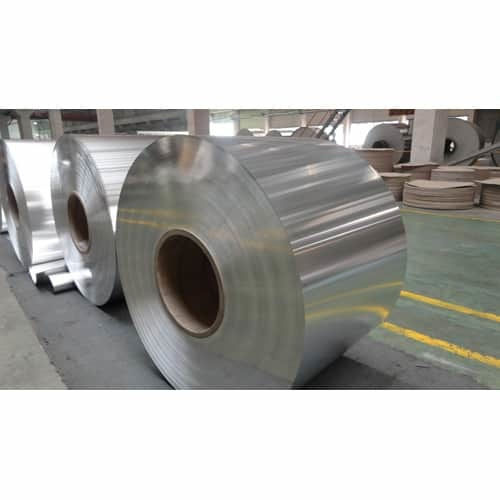

- शीट्स प्लेट्स आणि कॉइल

- स्टील चेन आणि अँकर

- कोन चॅनेल आणि फ्लॅट बार

- बनावट फिटिंग

- वाल्व आणि मेनफोल्ड

- अधिक माहिती

- आमच्याशी संपर्क साधा

Electrolytic Copper

160 INR/Kilograms

उत्पादन तपशील:

- उत्पादन फॉर्म Solid

- साहित्य रचना% Copper 99.99%

- गंज प्रतिरोधक Yes

- आकार Custom Sizes Available

- तन्य शक्ती 200 - 250 MPa

- पुनर्वापरयोग्य Yes

- कडकपणा 45-85 HV (Depends on temper)

- Click to view more

X

किंमत आणि प्रमाण

- 100

उत्पादन तपशील

- Bright / Matt

- 200 - 250 MPa

- Yes

- Custom Sizes Available

- Yes

- Up to 1084°C (Melting Point)

- Uncoated / Bare

- Copper (Cu) ≥ 99.99%

- Electrolytic Tough Pitch (ETP) Copper

- Available in various diameters (on request)

- Customizable as per requirement

- 45-85 HV (Depends on temper)

- Electrical Conductors, Electrical Applications, Industrial Components

- Reddish Brown

- 0.2 mm to 30 mm (Custom sizes available)

- Variable, depends on size and quantity

- 99.99% Pure Copper

- Copper 99.99%

- Solid

- Bright, Matt, Smooth Finish

व्यापार माहिती

- प्रति दिवस

- आठवडा

उत्पादन तपशील

Electrolytic Copper

Electrolysis can be used to produce ultra-pure copper (more than 99.95 percent purity), referred to as electrolytic copper. High purity is required because the vast majority of copper is utilized in the manufacture of electrical equipment, and even trace levels of copper impurity metals can significantly impact the metal's capacity to conduct electricity. Even a 0.05 percent concentration of arsenic impurity, for instance, will diminish the conductivity of the metal by 15%. Consequently, high-purity copper wires must be used to construct electric wires, especially when electricity is to be transported over long distances via high-voltage transmission lines. In addition, our organization sells electrolytic copper at a cheap price because of the high quality that has been maintained.

Unmatched Conductivity and Purity

Electrolytic Copper stands out with an impressive electrical conductivity of at least 101% IACS and a purity level of 99.99%. Carefully refined and thoroughly tested, this copper is ideal for high-performance electrical and electronic applications where minimal energy loss and maximum efficiency are essential. Its negligible impurity content, bright or matte surface finish, and customizable forms make it a trusted choice for both manufacturers and suppliers.

Flexible Forms and Custom Solutions

Available as strips, rods, wires, sheets, and plates, Electrolytic Copper is tailored to diverse requirements. Choose from a thickness range of 0.2 mm to 30 mm and variable diameters to suit any projectfrom intricate wiring and busbars to heavy-duty industrial machinery components. Bundled, palletized, or packed to client specifications, each order is shipped in protective packaging to ensure product integrity.

FAQs of Electrolytic Copper:

Q: How is Electrolytic Copper manufactured to achieve such high electrical conductivity?

A: Electrolytic Copper is produced through an advanced electrolysis process, which ensures superior refinement and exceptionally low impurity levels ( 0.01%). This meticulous manufacturing process results in electrical conductivity of at least 101% IACS, making it ideal for demanding electrical and electronic applications.Q: What applications benefit most from using Electrolytic Copper?

A: Electrolytic Copper is widely used in electrical conductors, wiring, busbars, transformers, switchgear, and industrial machinery components due to its excellent electrical conductivity, corrosion resistance, and mechanical strength. Its customizable forms make it suitable for a broad spectrum of industrial and electrical uses.Q: When should I choose Electrolytic Copper over other copper grades?

A: Select Electrolytic Copper when you need high purity (99.99%), zero lead content, and maximum electrical conductivity to meet strict industry standards or for use in sensitive electrical and electronic equipment. Its superior properties ensure reliable performance in critical and high-load applications.Q: Where can I source Electrolytic Copper with custom dimensions and finishes?

A: Electrolytic Copper is available through reputable manufacturers, exporters, suppliers, and importers in India, offering customized dimensions, thicknesses, and finishes (bright, matt, smooth) to match unique project requirements. Packaging is tailored to ensure safe delivery based on the customers specifications.Q: What is the process of obtaining Electrolytic Copper in specific forms?

A: Electrolytic Copper can be supplied as sheets, rods, wires, strips, or plates, and is processed according to client orders. Simply provide your dimensional and finish preferences, and manufacturers will produce and package the copper accordingly, with strict adherence to international standards.Q: How does Electrolytic Copper offer advantages in electrical applications?

A: This copper delivers unmatched electrical performance due to its extremely high purity, outstanding annealing capability, customizable forms, and resistance to corrosion. These advantages translate into efficient current flow, improved component durability, and minimal energy loss, making it invaluable for modern electrical infrastructure.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाईल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese