- होम पेज

- कंपनी प्रोफाइल

-

हमारे उत्पाद

- औद्योगिक बोल्ट

- एंकर फास्टनरों

- औद्योगिक पागल

- औद्योगिक वाशर

- सॉकेट पेंच

- मशीन पेंच

- स्वयं टैप करने वाला पेंच

- चूडीदार रॉड

- शिकंजा

- निकला हुआ किनारा

- औद्योगिक हुक

- पेचदार डंडा

- पाइप फिटिंग

- ट्यूब फिटिंग

- सीएनसी घटक और निर्माण

- साइफन ट्यूब

- शीट प्लेट और कुंडलियाँ

- स्टील की जंजीरें और एंकर

- कोण चैनल और फ्लैट बार्स

- जाली फिटिंग

- वाल्व और मैनिफोल्ड

- और जानकारी

- संपर्क करें

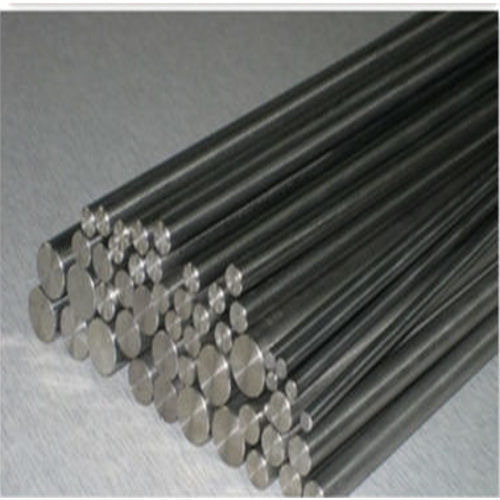

Inconel Round Bars

160 आईएनआर/Kilograms

उत्पाद विवरण:

- कठोरता Rockwell B 80-95 (varies by grade)

- उत्पाद प्रपत्र Solid Round Bar

- टेन्साइल स्ट्रेंथ Ultimate tensile strength 760–1035 MPa (varies by grade)

- पुन: उपयोग करने योग्य Yes

- कोटिंग का प्रकार Uncoated / As supplied

- साइज Standard and custom lengths up to 6 meters or as required

- सामग्री संरचना% Nickel 58-72%, Chromium 14-23%, Iron 5-21%, trace elements

- Click to view more

X

इनकोनेल राउंड बार्स मूल्य और मात्रा

- किलोग्राम/किलोग्राम

- 100

- किलोग्राम/किलोग्राम

- Hot Rolled/Forged/Cold Drawn

- 8.44 g/cm³ (for Inconel 625)

- Good, with recommended tools and speeds

- Non-magnetic in annealed condition

- Plain, Beveled, Threaded Ends as required

- Solution Annealed/Cold Finished/Hot Rolled

- 30-55% in 2" (varies by grade)

- Excellent

- Minimum 415 MPa (varies by grade)

- 1350-1400°C (varies by grade)

इनकोनेल राउंड बार्स उत्पाद की विशेषताएं

- Smooth, Peeled, or Polished

- Nickel-Chromium Alloy

- Customizable as per requirements

- Used in high-temperature and high-pressure environments

- Rockwell B 80-95 (varies by grade)

- Polished, Bright, Black, Peeled, Turned, Ground

- Nickel 58-72%, Chromium 14-23%, Iron 5-21%, trace elements

- Uncoated / As supplied

- Standard and custom lengths up to 6 meters or as required

- Yes

- Excellent resistance to oxidation and corrosion

- Inconel 600/625/718/800/825

- 6 mm to 300 mm

- Inconel 600, 625, 718, 800, 825

- Metallic Silver / Grey

- Ultimate tensile strength 760–1035 MPa (varies by grade)

- Solid Round Bar

- Variable depending on size and length

- Specified on order or as per standard sizes

- Yes

- Hot Rolled/Forged/Cold Drawn

- 8.44 g/cm³ (for Inconel 625)

- Good, with recommended tools and speeds

- Non-magnetic in annealed condition

- Plain, Beveled, Threaded Ends as required

- Solution Annealed/Cold Finished/Hot Rolled

- 30-55% in 2" (varies by grade)

- Excellent

- Minimum 415 MPa (varies by grade)

- 1350-1400°C (varies by grade)

इनकोनेल राउंड बार्स व्यापार सूचना

- 100 प्रति दिन

- 1 हफ़्ता

उत्पाद विवरण

Inconel Round Bars offered by our company, are used where corrosion resistance is an important criterion, or where operating temperatures preclude the use of aluminium. These bars are used for applications where a superior surface finish and exact dimensions are essential. They are used in different applications which include frameworks, supports, braces, shafts, and axles. Inconel Round Bars are highly corrosion resistant. These bars are used in a wide range of industrial applications from oil & gas and chemical to marine industries. They are great and safe to use.

Versatile End Conditions and Superior Machinability

Inconel Round Bars are provided with plain, beveled, or threaded ends to cater to different engineering requirements. Their good machinability enables precision fabrication using recommended tools and optimized cutting speeds, ensuring high-quality output for varied industrial uses.

Exceptional Performance in Extreme Environments

With superb corrosion and oxidation resistance, Inconel Round Bars outperform in high-pressure and high-temperature environments. Their composition ensures prolonged durability and stability in sectors like power generation, petrochemicals, and marine engineering, where reliability is paramount.

Stringent Manufacturing and International Standards

Produced via hot rolling, forging, or cold drawing, Inconel bars adhere to ASTM B166, ASTM B564, ASTM B637, and ASTM B446 standards. Each bar undergoes solution annealing, cold finishing, or hot rolling based on application needs, ensuring consistent mechanical and physical properties.

FAQs of Inconel Round Bars:

Q: How are Inconel Round Bars manufactured to ensure quality and consistency?

A: Inconel Round Bars are produced through hot rolling, forging, or cold drawing processes, followed by solution annealing or cold finishing. Each manufacturing stage follows strict ASTM standards (such as ASTM B166, B564, B637, B446) to deliver uniform mechanical performance and surface quality.Q: What machining considerations should be followed for Inconel Round Bars?

A: Machining Inconel requires using recommended carbide or high-speed steel tools at specified speeds and feed rates. Good machinability is achieved by maintaining proper coolant flow and selecting optimized cutting parameters to enhance tool life and surface finish.Q: Where are Inconel Round Bars commonly used?

A: These bars are extensively utilized in industries demanding high resistance to heat and corrosion, such as aerospace, chemical processing, power generation, oil and gas, marine engineering, and petrochemicals, owing to their durable performance under extreme conditions.Q: What are the benefits of using Inconel Round Bars in high-temperature applications?

A: Inconel bars exhibit excellent oxidation and corrosion resistance and can withstand temperatures up to 982C (1800F), making them ideal for high-temperature and high-pressure environments, ensuring extended service life and mechanical stability.Q: What is the typical composition and physical property profile of Inconel Round Bars?

A: Inconel Round Bars are primarily nickel (5872%), chromium (1423%), iron (521%), with trace elements. They have a density of 8.44 g/cm (Inconel 625), non-magnetic in annealed condition, and exhibit high yield (415 MPa min) and tensile strength (7601035 MPa, grade-dependent).Q: How customizable are the dimensions and end conditions of Inconel Round Bars?

A: Diameter ranges from 6 mm to 300 mm, with lengths up to 6 meters or as needed. Customers can specify plain, beveled, or threaded ends, and various surface finishes such as polished, bright, ground, peeled, or turned, making these bars highly adaptable to project requirements.Q: Is Inconel Round Bar material recyclable and environmentally friendly?

A: Yes, Inconel Round Bars are fully recyclable, contributing to sustainable manufacturing practices while maintaining excellent mechanical properties and corrosion resistance throughout their lifecycle.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese