- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

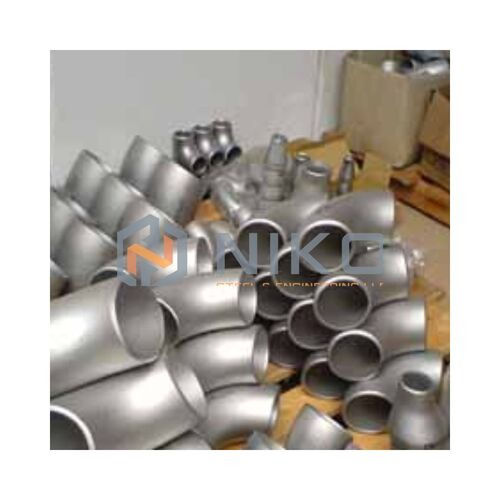

SS 347H BUTTWELD FITTINGS

200 INR/Kilograms

Product Details:

- Yield Strength 205 MPa min

- Connection Type Buttweld

- Temperature Range Up to 899C (1650F)

- Sealing Type Metal-to-metal

- Tolerance 0.5 mm

- Bend Radius As per ASME/ASTM specification

- Coating Type No coating (pickled & passivated only)

- Click to view more

X

SS 347H BUTTWELD FITTINGS Price And Quantity

- 200 INR/Kilograms

- 300 Kilograms

- Seamless / Welded

- 8.0 g/cm³

- Excellent in high-temperature and corrosive environments

- Beveled Ends

- Ultrasonic, Radiographic, and Visual Inspection

- High at elevated temperature

- 40% min at 20°C

- Solution Annealed

SS 347H BUTTWELD FITTINGS Product Specifications

- Welded

- 12.7 mm 1219 mm

- 515 MPa min

- SS 347H

- No coating (pickled & passivated only)

- Rigid

- Stainless Steel

- Oil & Gas, Petrochemical, Power Plant, Chemical Processing

- As per ASME/ASTM specification

- Schedule 10S/20/40S/80S or custom

- Elbow, Tee, Reducer, Cap, Stub End

- Round

- ASTM A403 / ASME SA403

- Pickled, Passivated

- 0.5 mm

- Class 150/300/600/900/1500

- Metal-to-metal

- 1/2 inch to 48 inch (DN15 - DN1200)

- Buttweld

- Up to 899C (1650F)

- 205 MPa min

- Buttweld Fittings

- As per standard or custom

- Piping and pipeline systems

- Silver

- Seamless / Welded

- 8.0 g/cm³

- Excellent in high-temperature and corrosive environments

- Beveled Ends

- Ultrasonic, Radiographic, and Visual Inspection

- High at elevated temperature

- 40% min at 20°C

- Solution Annealed

SS 347H BUTTWELD FITTINGS Trade Information

- Cash Advance (CA), Letter of Credit (L/C), Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque

- Within a certain price range free samples are available

- Australia, South America, Western Europe, Middle East, Africa, Central America, Asia, Eastern Europe, North America

- All India

- ISO CERTIFIED 9001:2015

Product Description

NIKO STEEL AND ENGINEERING LLP is one of the Prominent suppliers and trader of Stainless Steel 347H Pipe Fittings, which is a Dual - Stabilized Ferritic, steel with 18% Chromium. Stainless Steel 347H Elbow Butt Weld Pipe Fittings Exhibits good high temperature strength, Plus good corrosion resistance in many exhaust gas environments and good oxidation resistance at elevated temperatures. with excellent machinability, Stainless steel 347H Tee Butt Weld Pipe Fittings are also Characterized by consistent quality from melt to melt and Properties which accord exactly with the specifications. In stainless steel 347H Cross Butt weld Pipe Fittings, Machinability has been improved without jeopardizing properties such as corrosion resistance and mechanical strength. The Non metallic inclusions in stainless steel 347H Reducer Fittings are of great significance to the improved machinability.

SS 347H Short Radius Elbow Supplier, Stainless Steel 347H 180 Deg Bend , 347H Stainless Steel Reducer, Stainless Steel Reducer, Stainless Steel 10d Pipe Bend, 347H Stainless Steel End Cap, SS 347H Pipe Elbow, SS 347H Pipe Bend Supplier in India.

Exceptional Performance in Extreme Conditions

SS 347H Buttweld Fittings are tailored for applications where components must withstand high pressures and temperatures, reaching up to 899C (1650F). Their robust corrosion resistance makes them especially valuable in harsh processing and energy environments, ensuring system integrity over the long term. Precision manufacturing and strict quality testing further enhance their reliability for critical pipelines.

Comprehensive Standards and Versatile Applications

Designed in strict adherence to ASTM A403/ASME SA403, SS 347H Buttweld Fittings come in varied shapes and sizes, including elbows, tees, reducers, and more. The fittings' adaptability across multiple schedule thicknesses and diameter ranges makes them suitable for a wide spectrum of uses in oil & gas, petrochemical, chemical processing, and power plant piping systems.

FAQ's of SS 347H BUTTWELD FITTINGS:

Q: How are SS 347H Buttweld Fittings manufactured and quality-tested?

A: SS 347H Buttweld Fittings are produced using seamless or welded processes, followed by solution annealing for optimal material properties. Each fitting undergoes rigorous quality inspections, including ultrasonic, radiographic, and visual testing, ensuring structural integrity and compliance with industry standards.Q: What advantages does SS 347H offer in high-temperature and corrosive environments?

A: SS 347H stainless steel is stabilized with high chromium and added carbon, providing excellent resistance to corrosive attack and oxidation at elevated temperatures up to 899C (1650F). This makes these fittings an ideal choice for demanding industrial environments such as chemical processing and power plants.Q: When should I consider using SS 347H Buttweld Fittings in my piping system?

A: Opt for SS 347H Buttweld Fittings when your application requires exceptional thermal stability, high impact strength at elevated temperatures, and superior corrosion resistance, particularly in aggressive or high-temperature service conditions common in oil & gas, petrochemical, and power industries.Q: Where are SS 347H Buttweld Fittings typically used?

A: These fittings are commonly installed in piping and pipeline systems within oil & gas refineries, petrochemical facilities, power plants, and chemical processing plants. Their durability and resistance to harsh environments make them suitable for both new projects and replacement operations.Q: What is the benefit of pickled and passivated surface treatment for these fittings?

A: Pickling removes scale and surface impurities, while passivation creates a protective oxide layer, significantly enhancing the fittings' resistance to corrosion. This ensures a clean, smooth surface and extends the service life even in challenging environments.Q: How do the dimensional tolerances and thickness options affect installation?

A: With a tolerance of 0.5 mm and multiple thickness schedules (10S/20/40S/80S or custom), SS 347H Buttweld Fittings offer precise fit and flexibility for a wide range of pipeline designs, enhancing safety and ease during welding and assembly.Q: What is the primary benefit of the beveled end and metal-to-metal sealing type in these fittings?

A: The beveled end facilitates effective butt welding, resulting in strong, leak-proof joints. The metal-to-metal seal ensures a robust connection suitable for high-pressure, high-temperature applications without reliance on additional sealing materials.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese