- Home Page

- Company Profile

-

Our Products

- Industrial Bolts

- Anchor Fasteners

- Industrial Nuts

- Industrial Washers

- Socket Screw

- Machine Screw

- Self Tapping Screw

- Threaded Rods

- Screws

- Flanges

- Industrial Hooks

- Threaded Bar

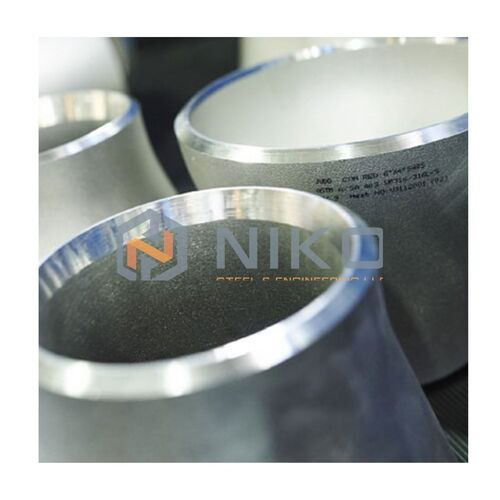

- Pipe Fittings

- Tube Fittings

- CNC Components And Fabrication

- Syphon Tubes

- Sheets Plates And Coils

- Steel Chains And Anchors

- Angle Channels And Flat Bars

- Forged Fitting

- Valves And Mainfold

- More Info

- Contact Us

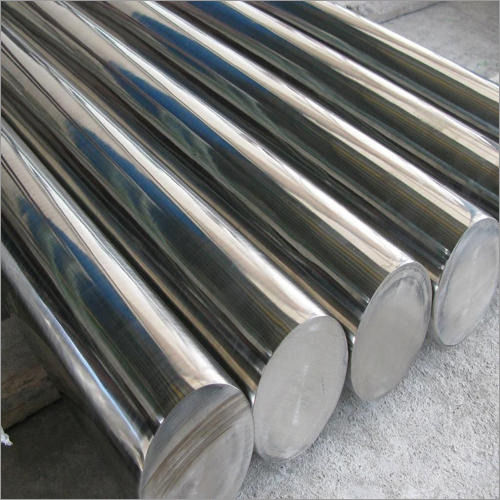

Nickel Alloy Rod

1000.00 - 10000.00 INR/Kilograms

Product Details:

- Product Type Nickel Alloy Rod

- Shape Rod (Cylindrical)

- Elongation 30% minimum (approximate)

- Strength High tensile strength, specific values depend on grade

- Hardness 70 - 95 HRB (depends on alloy and treatment)

- Resistance Excellent resistance to corrosion, oxidation, and acids

- Grade Nickel 200 / Nickel 201 / Inconel / Monel (as per requirement)

- Click to view more

X

Nickel Alloy Rod Price And Quantity

- 1000.00 - 10000.00 INR/Kilograms

- 1 Kilograms

- Up to 6 meters (can be customized)

- Bright / Polished

- +/- 0.05 mm

- Non-magnetic or slightly magnetic depending on alloy

- ASTM B160 / ASTM B564 / DIN / JIS

- Hot rolled / Cold drawn / Annealed

- 2 mm to 120 mm (customizable)

- Standard export packing (wooden boxes or bundles)

- Excellent performance at elevated temperatures

- Good weldability with appropriate filler metals

Nickel Alloy Rod Product Specifications

- Chemical processing, aerospace, marine, oil & gas, electrical, heat exchangers

- Excellent resistance to corrosion, oxidation, and acids

- Metallic Silver

- 1400C - 1450C

- Nickel Alloy Rod

- Nickel (Ni) with alloying elements such as Cr, Fe, Mo (varies by grade)

- 8.8 Gram per cubic centimeter(g/cm3)

- High tensile strength, specific values depend on grade

- 30% minimum (approximate)

- Rod (Cylindrical)

- Nickel 200 / Nickel 201 / Inconel / Monel (as per requirement)

- 70 - 95 HRB (depends on alloy and treatment)

- Up to 6 meters (can be customized)

- Bright / Polished

- +/- 0.05 mm

- Non-magnetic or slightly magnetic depending on alloy

- ASTM B160 / ASTM B564 / DIN / JIS

- Hot rolled / Cold drawn / Annealed

- 2 mm to 120 mm (customizable)

- Standard export packing (wooden boxes or bundles)

- Excellent performance at elevated temperatures

- Good weldability with appropriate filler metals

Nickel Alloy Rod Trade Information

- 50-60 Kilograms Per Week

- 1 Week

Product Description

Nickel Round Rod provided by our company, is known to be the hardest material, in the constructional industries. In fact, it is now used in so many different industries in place of the old form of the rods. It is said to be the toughest product because the material which is used in the product provide this quality to the product. Nickel Round Rod mainly used in those applications where the strength rods are required. It uses to add more quality to the product and extend it live for long.

Precision Manufacturing and Customization

Nickel Alloy Rods are available in a wide diameter range from 2 mm to 120 mm, with lengths customizable up to 6 meters. Whether hot rolled, cold drawn, or annealed, the rods meet strict tolerance requirements of +/- 0.05 mm, ensuring reliability for specialized needs. All products adhere to global standards such as ASTM B160, ASTM B564, DIN, and JIS for guaranteed quality.

Superior Performance for High-Temperature Applications

Engineered for environments requiring excellent temperature stability, our nickel alloy rods are widely used in chemical processing, aerospace, marine, oil & gas, electrical, and heat exchanger industries. The rods retain strength, ductility, and corrosion resistance even at temperatures above 1400C, making them a preferred choice where reliability and safety are paramount.

Corrosion Resistance and Weldability

Nickel alloy rods offer exceptional resistance to acids, oxidation, and corrosive elements due to their specific alloy compositions containing Ni, Cr, Fe, and Mo. These characteristics, coupled with their good weldability using the right filler metals, make them suitable for applications where both durability and maintainability are essential.

FAQ's of Nickel Alloy Rod:

Q: How are nickel alloy rods customized to meet specific project requirements?

A: Nickel alloy rods can be tailored in diameter (2 mm to 120 mm) and length (up to 6 meters) and manufactured using hot rolled, cold drawn, or annealed processes. Customization allows for precise dimensional and grade requirements, meeting application-specific needs in industries like aerospace or chemical processing.Q: What surface finish does the nickel alloy rod have and why is it important?

A: Our nickel alloy rods are available in bright or polished finishes, providing both aesthetic appeal and functional benefits such as reduced surface oxidation and enhanced resistance to corrosion. These finishes are ideal for environments where both performance and appearance are critical.Q: When should a specific grade like Nickel 200, Inconel, or Monel be selected?

A: The choice of grade depends on application needs: Nickel 200/201 suits general corrosion resistance and electrical applications; Inconel is selected for high-temperature and aggressive environments; Monel offers excellent resistance to acids and seawater, ideal for marine and chemical processing uses.Q: Where are nickel alloy rods commonly used?

A: Nickel alloy rods are frequently utilized in chemical plants, aerospace components, marine equipment, oil & gas installations, electrical systems, and heat exchangers thanks to their strength, temperature stability, and resistance to harsh corrosive conditions.Q: What benefits do these rods provide over standard steel or stainless steel rods?

A: Compared to steel or stainless steel, nickel alloy rods provide superior resistance to corrosion, oxidation, and acid attack, maintain strength at high temperatures, and have excellent elongation (approximately 30%), making them more reliable for critical applications in challenging environments.Q: How is the quality and tolerance of nickel alloy rods assured during manufacturing?

A: Each rod is produced under strict quality controls adhering to international standards (ASTM, DIN, JIS), with precise tolerances of +/- 0.05 mm. Rigorous testing ensures mechanical properties, chemical composition, and surface finish meet application and safety criteria.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese